↧

Small Arms Developed By ARDE & OFB

↧

Missing The Woods For The Trees

All it takes for the Indian component of cyberspace to go into a senseless tizzy is for a ‘Bandalbaaz’ masquerading as a journalist to highlight selected quotes from a certain Minister’s interaction during a media conclave, and draw spectacularly outrageous conclusions. This in turn gets to be ‘assumed’ as being the gospel truth, with the end-result being a classic case of the blind leading the blind. Take, for instance, the following two selective quotes that originated 48 hours ago:

“By buying 36 Rafales instead of 126, I have saved the cost of 90 Rafales,” Parrikar said, adding that this amount was around Rs.900 billion (US$15.51 billion). “We will use this money to buy Tejas LCA pricedat around Rs.1.5 billion each,” he added.

“By buying 36 Rafales at a price less than (what was quoted in response to) the earlier tender for 126aircraft, I have saved the cost of 90 Rafales. We will use that money to buy Tejas LCAs”.

Now here’s what it all means. Under the original M-MRCA procurement process for an initial 126 Dassault Aviation Rafales, the first 18 (12 single-seaters and six tandem-seaters) were to be acquired in flyable condition off-the-shelf, for which the Ministry of Defence (MoD) would have had to pay only the acquisition costs and related support infrastructure costs. For the remaining 108 Rafales that were to be licence-built in India (74 single-seaters and 34 tandem-seaters of which 11 were be built from semi-knocked down or SKD kits, 31 from completely knocked down or CKD kits, and 66 made from indigenously manufactured kits or IMK), the MoD would have been required to fork out A) the industrial production costs (for setting up the domestic industrial infrastructure and training a skilled pool of human resources); B) acquisition costs that were to be paid to the MoD-owned Hindustan Aeronautics Ltd (HAL); and C) support infrastructure costs for creating the squadron-level and intermediate-level MRO facilities.

Now that the original scheme for procuring 126 Rafales (plus 63 options) has been abandoned, the MoD will, under Phase-1, be required to pay only the acquisition costs and related support infrastructure costs for the first 36 Rafales. Under Phase-2, an industrial consortium comprising Dassault Aviation and its Indian counterparts from both the private-sector and public-sector will supply up to 153 locally-assembled Rafales. This consortium—to be dominated by the private-sector—will raise the necessary funding required (for creating the domestic industrial infrastructure and training a skilled pool of human resources) entirely from the capital markets, and will charge the MoD only for the fleet acquisition cost. In other words, the MoD’s Department of Defence Production & Supplies will no longer be required to foot the bill for industrial production costs of the 171 Rafales.

Consequently, this enormous pool of money saved will be invested in R & D activities for the Indian Air Force’s Tejas Mk2 MRCA and the Indian Navy’s LCA (Navy) Mk2. Since both these MRCAs will be brand-new designs, at least five flying prototypes for each type will be required to be built, and each type—Tejas Mk2 and LCA (Navy) Mk2—will be required to undergo at least 2,000 hours of flight-tests before they are awarded their respective airworthiness certifications. For all intents and purposes, these are herculean tasks that require substantial R & D funding-levels, about which I will soon elaborate further in greater detail below.

Standoff DEW For SEAD

Standoff DEW For SEAD

But first, let’s dissect the joint India-Israel project to co-develop an air-launched, standoff EMP-emitting missile, which, for all intents and purposes, will be India’s first operational precision-guided directed-energy weapon (DEW). It may be recalled that in the night of September 6, 2007 in the desert at Al Kibar, 130km (81 miles) from the Iraqi border and 30km from the northern Syrian provincial city Deir el-Zor, a fleet of ten IDF-AF F-15Is conducted OP Orchard, which involved the destruction of heavy-water reactor then under construction with North Korean expertise and Iranian funding. In that raid, the IDF-AF had used a RAFAEL-developed precision-guided, standoff DEW to shut down Syria’s ground-based air-defence sensors—a move that would go on to be the optimum model for future surgical air-strikes.

Israel offered to co-develop a variant of this DEW with India on July 7, 2008 during an official meeting in Pune with the DRDO. This was followed by two additional meetings held in Delhi with senior DRDO and IAF officials in August and September 2008. The joint R & D project officially began in mid-2010 and series-production of this DEW will commence later this year, with the Kalyani Group being the prime industrial contractor from the Indian side.

This air-launched, fire-and-forget, expendable DEW, whose main role is to render electronic targets useless, will make use of the airframe of RAFAEL’s Spice 250 rocket-powered PGM, and will have a range of 120km. It is a non-kinetic alternative to traditional explosive weapons that use the energy of motion to defeat their targets. During a mission, this missile will navigate a pre-programmed flight plan (using fibre-optic gyros) and at pre-set coordinates an internal active phased-array microwave emitter will emit bursts of selective high-frequency radio wave strikes against up to six different targets during a single mission.The EMP-like field which will be generated will shut down all hostile electronics. Thus, the whole idea behind such a weapon is to be able to destroy an enemy’s command, control, communication and computing, surveillance and intelligence (C4SI) capabilities without doing any damage to the people or traditional infrastructure in and around it. In other words, it can eliminate an air-defence facility’s effectiveness by destroying the electronics within it alone, via a microwave pulse, without kinetically attacking the facility itself.

For the IAF, this air-launched DEW will be a ‘first day of war’ standoff weapon that can be launched outside an enemy’s area-denial/anti-access capabilities, and fly a route over known C4SI facilities, zapping them along its way, before destroying itself at the end of its mission. Because of its stealthy design, long-range and expendability, it will fly where no other manned airborne assets could and because it does not blow anything up, its use does not necessarily give away the fact that the enemy is under direct attack in the first place. In that sense, it is also a psychological weapon, capable of at least partially blinding an enemy before it even knows that a larger-scale air-attack is coming. The IAF plans to arm its upgraded Mirage 2000Hs and the yet-to-be-acquired Rafale MMRCAs with this DEW and also with RAFAEL’s Spice-1000 PGM.

Interestingly, Ukraine last February during the Aero India 2015 Expo was also showcasing an air-launched DEW, whose poster is uploaded below.

↧

↧

Aero India 2015 Show Report-1

Let us begin on a lighter note, before proceeding to more serious and horrifying matters. Firstly, take a look below at the booth of Italy’s Finmeccanica Group. For reasons unknown to me, this aerospace OEM was allowed to participate in the expo, but was either not allowed to exhibit its products and services, except for its wall-posters, or its exhibits were all rendered invisible by some novel cloaking technologies that were being showcased at the expo!

Which brings us to an incredulous demonstration of creative advertising—surprisingly from a Ministry of Defence-owned defence public-sector undertaking like Bharat Electronics Ltd (BEL). This is a classic case of either creativity going ballistic, or acute myopia. While one would have expected such advertisements (published in all show dailies that were distributed at the expo) to portray India-designed/built platforms like the Arjun Mk1 MBT, Project 17 FFG or Project 15A DDG, and the Tejas Mk1 LCA, in reality BEL appears to be trying to claim that its products are on board the General Dynamics Land Systems-built M-1A2 Abrams, and Lockheed Martin Littoral Combat Ship and F-16 Fighting Falcon MRCA!

Now, take a look below at the pathetic exhibitor booth of the Indian Space Research Organisation (ISRO).

Although Aero India 2015 was meant to be an aerospace expo, this did not prevent OEMs like the Kalyani Group from publishing advertisements in the show dailies about its Bharat-52 towed 155mm/52-calibre howitzer.

Now, read below what the MoD-owned Ordnance Factory Board (OFB) has to say about future supplies of all types of 155mm howitzers to the Indian Army in the years to come.

Now to the horrifying revelations emanating from the expo, which will be uploaded in the following threads.

↧

Badlands Of 'Eastern Nagaland' Inside Myanmar

But what follows below is a far bigger internal problem.

The ARIF (below) was once supported by Bangladesh in the 1980s, but is now a defunct outfit. It may, however, be revived with the assistance of ISIS.

Data On The Infamous Chittagong Arms Haul

Below is a detailed listing of all the separatist insurgent groups operating in and around North East India.

Below is the detailed chronological account of China’s association with various separatist insurgent groups active in both India's North East and northwestern Myanmar. Such an exhaustive compilation of data for public consumption has never before been undertaken by any Indian journalist. It was done for the very first time by Bangkok-based Swedish journalist Bertil Lintner for his book, titled GREAT GAME EAST: India, China And The Struggle For Asia’s Most Volatile Frontier.

↧

Myanmar Opts For CATIC's FC-1 Light MRCA

Myanmar last March became the second export customer (after Pakistan) for the FC-1 ‘Xiaolong’ light multi-role combat aircraft (MRCA) when it inked a contract with the Chinas Aero Technology Import-Export Corp (CATIC) for an initial 12 aircraft along with a cockpit procedures trainer, while retaining the option to procure another 12 at a later date.

Deliveries are scheduled to begin in December 2017 and these FC-1s will eventually replace Myanmar’s existing Xi’an F-7M Airguard and Nanchang A-5IIIC combat aircraft, which had been procured in the early 1990s.

The FC-1’s formal R & D process began when Pakistan inked a procurement contract with CATIC in 1999.

The MRCA’s design was frozen by China’s 611Institute in February 2001. Subsequently, six flying prototypes were built by the Chengdu Aircraft Corp (CAC). The first prototype was rolled out on May 31, 2003 and its maiden flight took place on August 25, 2003. The third prototype, built to series-production standards, first flew on April 9, 2004. The fourth prototype flew in April 2006.

The first tranche of six FC-1s, known as JF-17 Thunder Block-1, was delivered in flyaway condition to the Pakistan Air Force (PAF) between March and April 2008.

Following this, a supplementary contract for 42 more JF-17s was inked on March 7, 2009. Of these, only the first two were delivered in flyaway condition, while the remaining were supplied in semi-knocked-down (SKD) condition to the Kamra-based Pakistan Aeronautical Complex (PAC). The first PAC-assembled JF-17 was rolled out on November 23, 2009.

To date, CAC has delivered 50 JF-17 Block-1s and four JF-17 Block-2s (featuring a fixed aerial refuelling probe), with another 46 JF-17 Block-2s due for delivery by 2020. CAC is building them at a rate of eight per year.

The RD-93 turbofans for both the FC-1 and its JF-17 version are produced by the Moscow-based Chernyshev Machine-Building Plant, a subsidiary of Russia’s United Engines Corp (UEC) and supplied to CATIC.

The PAF plans to procure 50 Block-3 versions of the JF-17 in the following decade and each of these are likely to be equipped with a FWS-13 Taishan turbofan (now being flight-tested on board an IL-76MD testbed at the PLAAF’s China Flight Test Establishment at Xian-Yanliang air base in Xi’an, Sha'anxi province), passive electronically scanned array multi-mode radar (PESA-MMR) along with a CATIC-supplied infra-red search-and-track (IRST) sensor and a Sicong Group-developed helmet-mounted display system (HMDS).

CATIC is presently developing the JFT-17, a tandem-seat operational conversion trainer that is expected to make its maiden flight by the year’s end.

Data On FC-1’s Avionics Suite

FC-1’s Weapons Package

The CPMIEC-developed CM-400AKG supersonic air-launched ASCM has a terminal cruise speed of Mach 3 and a maximum range of 120km.

↧

↧

Spooks: Ours And Theirs

Here is what we do or like to do:

And what follows below is how it is done by a superpower:

He was reportedly the most successful and valued agent/asset the United States had run inside the Soviet Union in two decades. His documents and drawings had unlocked the secrets of several of the USSR’s radars and guided-weapons R & D years into the future. He had even smuggled circuit-boards and blueprints out of the R & D laboratories where he was working. His espionage thus put the US in a position to dominate the skies over hostile airspace and confirmed the vulnerability of USSR-developed air-defence networks. The agent was Adolf Tolkachev, an engineer and specialist in airborne radars who worked deep inside the Soviet military-industrial complex. Over a six-year perriod, Tolkachev met with his CIA handlers 21 times on the streets of Moscow. Tolkachev’s story has now been detailed in 944 pages of previously secret CIA cables about the operation that was declassified without condition for the forthcoming book, ‘The Billion Dollar Spy’. The CIA did not review the book before publication. The documents and interviews with the participants offer a remarkably detailed picture of how military-industrial espionage was conducted in the USSR during some of the most tense years of the Cold War. Tolkachev was driven by a desire to avenge history. His wife’s mother was executed and her father sent to forced-labour camps during Stalin’s Great Terror of the 1930s. He also described himself as disillusioned with communism and “a dissident at heart”. He wanted to strike back at the USSR, and did so by betraying its military secrets to the US.

His CIA case officers often observed that he seemed determined to cause the maximum damage possible to the Soviet Union, despite the risks. The punishment for treason was execution. Tolkachev did not want to die at the hands of the KGB. Therefore, he asked for and got a suicide pill from the CIA he could use if caught. The US Air Force estimated at one point in the operation that Tolkachev’s espionage had saved the United States $2 billion in weapons R & D. Tolkachev used to smuggle most of the secret documents out of his office during lunch-hour hidden in his overcoat, and photographed them using a Pentax 35mm camera clamped to a chair in his apartment. In return, Tolkachev asked the CIA for money, mostly as a sign of respect. There wasn’t much to buy in shortage-plagued Moscow in those days. He also wanted albums of Western music—the Beatles, Led Zeppelin, Uriah Heep and others—for his teenage son. Tolkachev thus became one of the CIA’s most productive agents of the Cold War.

Documentation supplied by Tolkachev by late 1983 had included: complete sets of engineering and technical data-packages of Phazatron NIIR’s 385kg N-019 Rubin RPLK-29/Sapfir-29 pulse-Doppler radar with twist-cassegrain antenna and its successor, the NO19MP Topaz—both meant for the MiG-29B-12 and MiG-29B-13; complete sets of engineering and technical data-packages of JSC V Tikhomirov Scientific Research Institute of Instrument Design’sN-001 Myech/RPLK-27 X-band pulse-Doppler radar with twist-cassegrain antenna for the Su-27SK;complete sets of engineering and technical data-packages of the ZaslonRP-31/N-007 PESA radar on-board the MiG-31; complete sets of engineering and technical data-packages ofthe Shmel 3-D radar for the Beriev A-50 AEW & CS from NPO Vega; and complete sets of engineering and technical data-packages of both 2K12 Kub MR-SAM familyand the Buk-М1 MR-SAM.

↧

New-Generation IRST Systems From China

↧

PLAAF's BMD Network Takes Shape

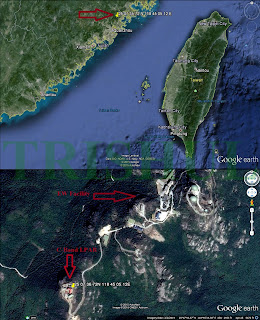

China’s People’s Liberation Army Air Force (PLAAF) has taken the first concrete step towards the establishment of a national ballistic missile defence (BMD) system with the construction of an initial two long-range C-band active phased-array radar systems (LPAR). The first such LPAR is already operational north of Huian in Fujian Province, facing Taiwan, while the second LPAR is now being built in Sichuan province, meaning it will be India-specific.

The LPAR north of Huian is made up of a single octagonal antenna-array of a CEIEC-developed C-band active phased-array radar that is located at Dongjing Shan, which is close to the PLAAF’s Huian-based electronic warfare (EW) facility in Fujian Province. This EW facility has been optimised to cause electronic degradation of Taiwan’s UHF-band Raytheon-supplied FPS-115 LPAR system at Leshan Mountain in Hsinchu County.

Construction of the PLAAF’s first new-generation LPAR commenced in 2008, and its hilltop-mounted octagonal fixed-array is boresighted along an azimuth of approximately 144 degrees. With an assumed coverage of +/-60 degrees in azimuth, this LPAR is theoretically capable of monitoring the entire Taiwan Strait region, as well as the southern approaches to the South China Sea. This LPAR can thus be used for providing long-range coverage extending north to Japan and to The Philippines.

So far, China has not yet revealed the design of the LR-SAM that will be used for BMD, but it is estimated that the final end-product, still undergoing development, will bear a close resemblance to Russia’s 9M82 and 9M83 family of hyper-velocity LR-SAMs.

Taiwan’s FPS-115 LPAR has been fully operational since February 2013. Its procurements origins date back to 2000 when its sale was approved by the Clinton Administration under the Surveillance Radar Programme (SRP). Competing against Lockheed martin, Raytheon won the $800 million contract in 2004 and began sub-systems deliveries in 2009. Construction delays due to landslides and technical issues forced Taiwan to agree to pay an additional $397 million in charges to finish the SRP, which has been described as being one of the most unique long-range airspace surveillance systems ever built. Japan is now attempting to catch up with the fielding of Raytheon-built AN/TPY-2 long-range, X-Band air-defence radars, which were originally designed as ground-based mobile target acquisition-cum-engagement radars for the Terminal High Altitude Area Defense (THAAD) system.

This LPAR is reported to have a range of 5,000km (3,100nm), and it is able to track a golf ball-sized target out to 3,000km. Taiwan can see almost all of China’s significant combat aircraft sorties and exercises from this radar. The requirement for such a powerful surveillance platform came about at China’s instigation. During the 1995-1996 Taiwan Strait missile crisis, China had launched ten DF-15 short-range ballistic missiles (SRBM) into the waters north and south of Taiwan. The intent was to discourage Taiwan from conducting its first democratic elections, but it failed. The US had then responded by sending two aircraft carrier battle groups to the area as a show of support. At that time, the PLA’s 2nd Artillery Corps had approximately 350 DF-11/DF-15 SRBMs, but today that number is about 1,100. Taiwan responded to the threat by procuring three Batteries of Raytheon MIM-104 Patriot Advanced Capability-2 (PAC-2) LR-SAMs for $1.3 billion. These were stationed around the capital city of Taipei, leaving much of the central and southern part of the island unprotected, except for a US-supplied air-defence missile system (supplied by GTE-Sylvania) in the late 1980s and using Taiwan-developed LR-SAMs, with the entire system being known as the Tien Kung 2 (Sky Bow-2).

Though Taiwan’s military and the US Pentagon pushed Taiwan to proceed with the procurement of the MIM-104 Patriot PAC-3 systems, domestic politics in Taiwan slowed progress on the deal until 2007, when the US released a ‘Patriot Configuration 2 Ground Systems Upgrade’ for the older PAC-2s for $939 million. In 2008, the US released 330 PAC-3 missiles, and in 2010, the US released an additional 114 PAC-3 missiles.

The US Air Force’s Defense Security Program (DSP) reportedly has real-time access to the data collected by Taiwan’s FPS-115 LPAR. The DSP monitors ballistic missile launches and nuclear detonations worldwide. The US in turn has reportedly given Taiwan free real-time access to early warning alerts generated by the DSP’s SBIRS satellite constellation since the last 10 years as quid pro quo.

↧

Fitments Of Project 15A DDG INS Kolkata D-63

Official press-briefings of the type given by the Indian Navy (IN) on August 13 regarding the INS Kolkata D-63—the first of three Project 15A guided-missile destroyers (DDG) on order for the IN—are always important for two reasons: for what is disclosed, and for what is not. For instance, while the IN stated that INS Kolkata is 90% indigenous by cost, it never went beyond that (thereby repeating history, for, on April 29, 2010, the IN had claimed that the total indigenous effort accounted for 60% of the cost of producing each Project 17 guided-missile frigate (FFG). My personal estimation is that in terms of hardware, INS Kolkata can boast of less than 50% indigenous content. And each Project 15A DDG’s acquisition cost is almost US$950 million (Rs.38 billion), while that of each Project 17 FFG is US$650 million (Rs.26 billion). The cost escalation in these two shipbuilding projects has been about 225% for Project 15A, about 260% for Project 17, with the main reasons contributing towards cost escalations being: delay in supply of warship-building D-40S steel by Russia, escalation due to increases in expenditure of the services rendered by Russian specialists on account of inflation during the build-period, impact of wage revisions due from October 2003, and finalisation of cost of weapons and sensors.

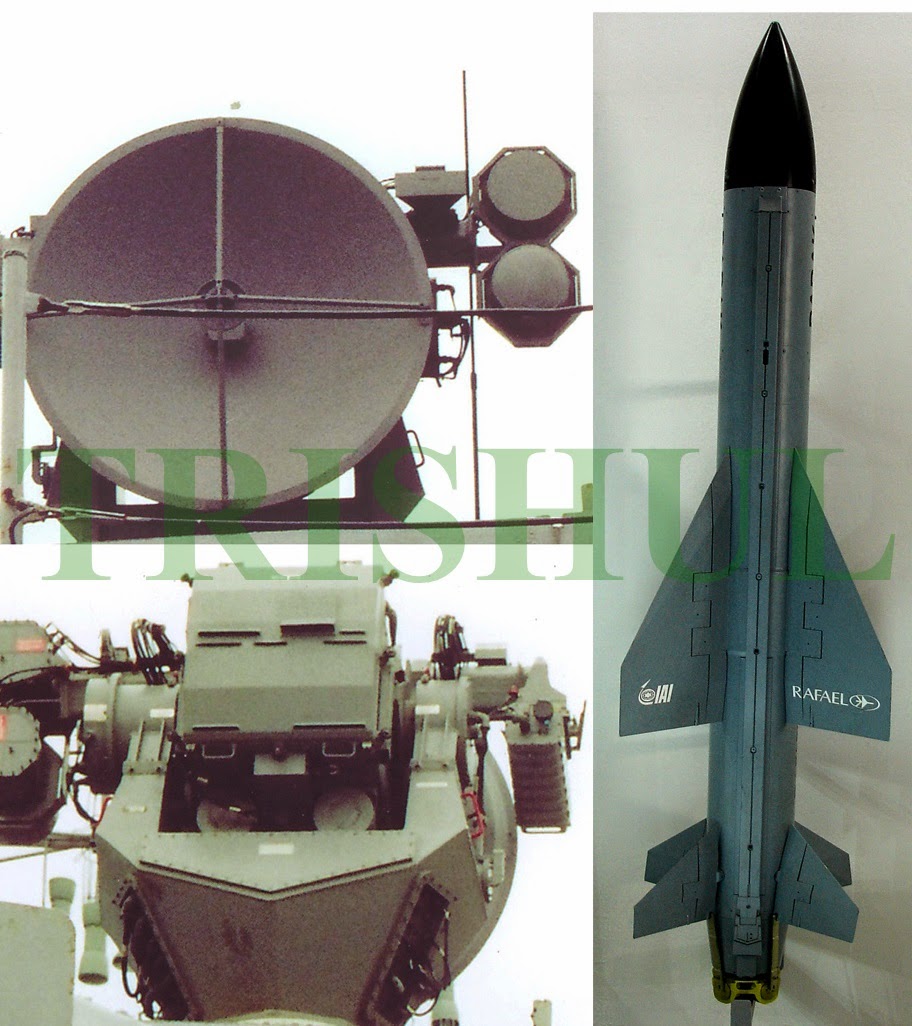

INS Kolkata, whose keel was laid down on September 23, 2003, was launched on March 30, 2006. Therefore, detailed design of this class of DDG (using TRIBON CAD software) by a joint team comprising the IN’s in-house Directorate of Naval Design (DND)—which celebrates its 50 years of existence this year—and the MoD-owned shipbuilder Mazagon Docks Ltd (MDL), should have been concluded by mid-2002. But this was not to be, since the weapon-and-sensor fitments were yet to be selected at that time. It was only on January 27, 2006 that India’s MoD-owned Defence R & D Organisation (DRDO) and Israel Aerospace Industries (IAI) inked the Barak-2 LR-SAM’s joint five-year joint R & D contract—valued at US$556 million—following 17 months of exhaustive negotiations. And the follow-on US$1.1 billion procurement contract for Barak-2 LR-SAMs and the three EL/M-2248 S-band multi-function search-and-target acquisition radars (MF-STAR)—the first naval active phased-array radars to become operational with a navy of the Indian Ocean Region (IOR)—was inked in April 2009. As a result, it can be safely inferred that the DND had finalised only about 70% of the DDG’s design by 2003.

What cannot be denied, however, is that the IN’s DND and its captive centre of excellence—the Weapons & Electronics Systems Engineering Establishment (WESEE)—along with MDL, have succeeded in fabricating and delivering an engineering marvel, despite several institutional handicaps. For instance, designing and building the main mast housing the EL/M-2248 was no small achievement. This APAR comprises four 3 x 3-metre fixed-array faces (each weighing 1,500kg) based on a modular tile-array architecture providing full 360-degree coverage. Liquid cooling is used to dissipate heat at the arrays. The EL/M-2248’s on-board processors and power-suppliers together weigh 900kg and are housed within six cabinets--two for the processors and four for the power-supply hardware. The entire MF-STAR suite thus weighs 6,900kg.In addition to 3-D long-range airspace volume search, the EL/M-2248 simultaneously provides ASCM approach warning; target classification; maritime surface surveillance; active and semi-active SAM support; fire-control for the OTOBreda 76/62 SRGM; and multiple targets engagement capabilities. It can detect a combat aircraft flying at high altitude at ranges of up to 250km, while an incoming ASCM can be detected at ranges of up to 25km.

The INS Kolkata’s CMS-15A combat management system (CMS), developed by the WESEE, includes the IAI-developed Weapon Control System (WCS), which performs threat evaluation and resource allocation functions, thereby optimising the capabilities of the CMS. The WCS thus provides simultaneous long-range volume search, threat alert, target verification/acquisition, target classification, track-while-search, and dedicated track, multi-long-range intercept support, and kill assessment capabilities. It is also characterised by:

* Wide intercept envelopes against a wide variety of targets.

* Quick reaction, short response time and minimum intercept range, these being crucial in scenarios of late target detection, high-speed attacking weapons, and restrained response policy.

* Long-range area defence.

* Simultaneous multi-target engagement capability and multi-missile co-existence capability for ensuring effectiveness against saturation attacks.

* De-confliction and coordination capabilities in dense and complex scenarios.

* Advanced ECCM features.

* Built-in threat evaluation, resources allocation and engagement coordination with other on-board defence systems.

* 2-way data-link with LR-SAMs (housed within eight 8-cell modules each weighing 1,700kg) increases mission success and target selectivity by providing the missile with real-time in-flight targetting updates, and providing real-time kill assessment to support shoot-look-shoot operations.

* Multi-system interoperability (task force-level as well as carrier battle group-level operations), under which each system may operate either as a standalone unit, supported by own sensors for engagement and guidance; or integrated in a multi-warship task force. Joint task force-level operation enables coordinated engagement of threats, mission optimisation (engaging each target with the optimal interceptor, in the optimal time) and resource sharing.

* Advanced Net-of-Nets architecture to ensure interoperability with other air-defence assets, such as remote/airborne radars mounted on aerostats) and external command-and-control centres).

* The Barak-8 LR-SAM’s flexible dual-pulse motor propulsion system provides high manoeuvrability at target interception range throughout its wide envelope.

* High-performance missile warhead specially designed for catering to a wide variety of airborne targets, and which guarantees robust target destruction.

* Built-in fratricide avoidance for undertaking safe air-defence operations near friendly air-traffic.

* Gunnery support capability, including combined missiles/gun engagement.

Expected To Go On-Board In Future

Or

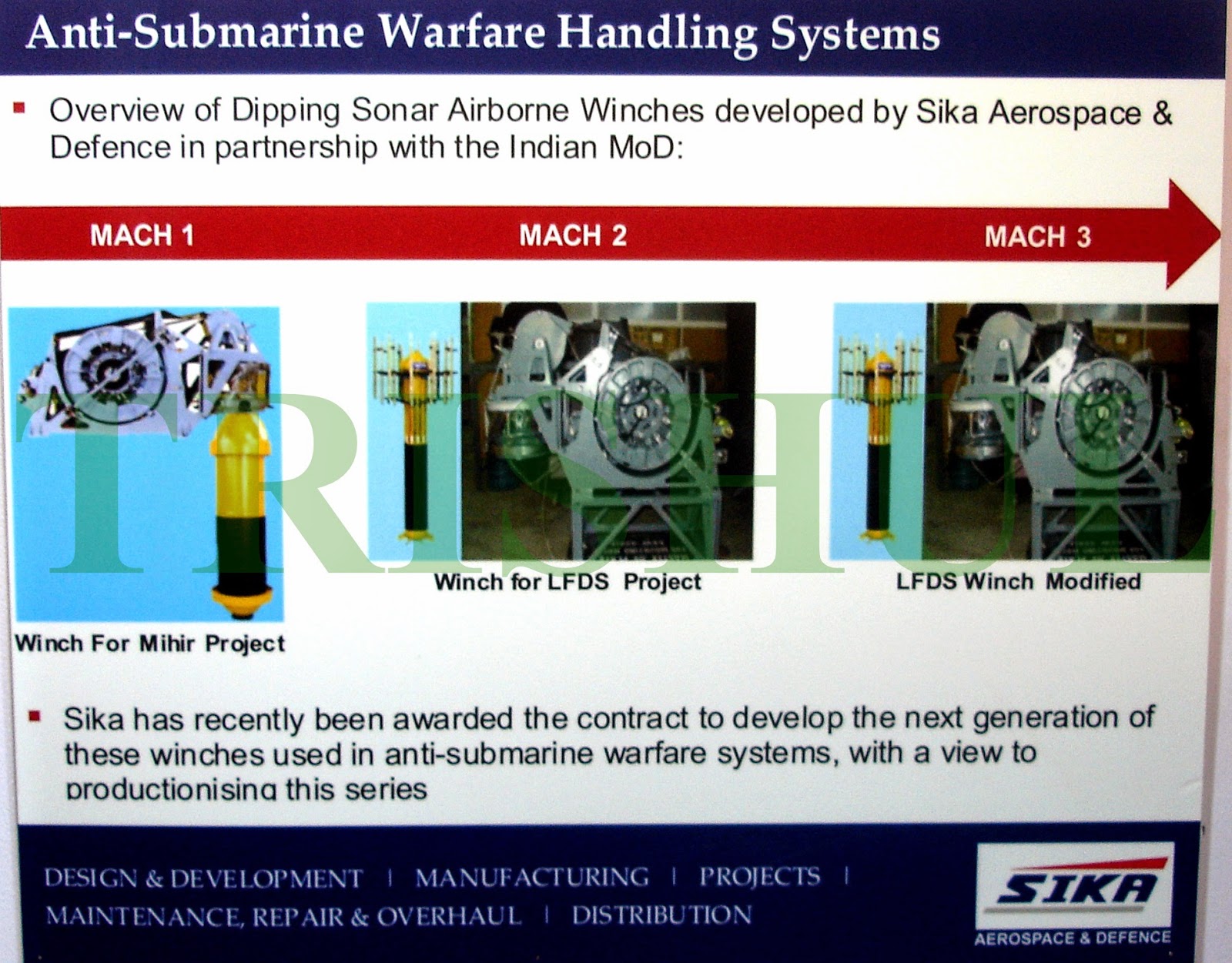

Though it was way back in late 2007 that the IN was introduced to the concept of operating remote-controlled RHIBs equipped with dunking sonars, it was only in late 2011 that the IN decided to acquire such systems since, unlike active/passive towed-array variable-depth sonar, the dunking sonar-on-a-RHIB can be operated in both shallow and deep waters (up to an operational depth of 300 metres or 985 feet), are easily and quickly deployed, are much cheaper and impose no restrictions whatsoever on warship manoeuvrability, especially in situations when a warship is being engaged by wire-guided heavyweight torpedoes. It is for all these reasons that the IN in early 2012 refused to order either the NAGAN active/passive towed-array variable-depth sonar that was being developed by the DRDO’s Naval Physical & Oceanographic Labs (NPOL) or the ATLAS Elektronik-developed ATAS, which had earlier been selected after competitive bidding for the three Project 15 DDGs and three Project 1135.6 Batch-1 FFGs. The IN now plans to acquire a few ROVs from Textron Systems and equip them with the NPOL-developed LFDS, with all structural and systems integration work being done by a joint team of personnel hailing from NPOL and WESEE.

But what accounts for the long delays in commissioning INS Kolkata? Obviously, MDL cannot be blamed since it is the IN’s DND that was unable to freeze the Project 15A DDG’s design concept well before the commencement of hull construction. Another reason for the delay has been the WESEE’s inability to build either a dedicated shore-based facility for undertaking weapons-and-systems integration R & D, or to acquire a test vessel for on-board tests-and-trials of various sensors, weapon systems and propulsion sub-systems. Contrast this with what China’s PLA Navy (PLAN) has done for undertaking similar activities: at the PLAN’s Wuhan Naval Research Facility at Huangjia Lake southeast of Wuhan, a giant full-scale replica of the top-deck, island and citadel of the PLAN’s first aircraft carrier (Liaoning 16) was built, and a similar effort is now underway there to build a full-scale mock-up of the citadel and integrated mast of the PLAN’s futuristic Type 055 DDG.

In addition, since March 1997, the PLAN has acquired at least three test vessels, with the first of these being the 6,000-tonne Dahua-class vessel (Shiyan 891) that was built by Shanghai-based Hudong-Zhonghua Shipyard and became operational in January 1998. The second such vessel—Hua Luogeng 892—was commissioned in August 2005. The third vessel—893—was commissioned in November 2011. It features a raised-bow breakwater to reduce water over the bow and a never-before-seen 30-feet-tall, 3-feet-diameter SATCOMS antenna on the forecastle. The ship has an enclosed foremast instead of the latticework mast structures found on 891 and 892. The foremast’s three yardarms feature new paired round flat-faced ESM antennae, plus radomes housing weapons targetting Ku-band and UHF-band data-link antenna.

↧

↧

Heading In The Right Direction.....At Last!

Matters have now progressed just as I had predicted (http://trishul-trident.blogspot.in/2014/08/blindly-muddling-through-with-eyes-wide.html). At last, the AgustaWestland AW-101 VVIP transportation helicopter procurement process is back on track! The terms, which have been cleared by the Attorney General, state that:

* All ongoing contracts will continue unhindered.

* All contracts related to spares will continue.

* Contracts with Russian manufacturers, where Finmeccanica is involved in the back-end, will continue.

* Finmeccanica will be allowed to participate in all tenders but if there are multiple options, Finmeccanica will not be considered regardless of the competitiveness of the offer.

* However, where Finmeccanica is the single vendor with no other firm providing options, the Govt of India is empowered to go ahead with the deal.

Looks like logical reasoning, sanity and common-sense are all staging a gradual comeback into India and the process of redeeming national honour and self-resilience has begun at long-last. My hearty congratulations to IAF HQ for doggedly persisting in trying to convince the Govt of India to objectively and dispassionately arrive at conclusions based on the merits of the case. For the past two years I too have been on a similar lonely crusade and I was perhaps the sole voice that took on the task of systematically exposing the sheer ignorance of those ‘desi’ journalists who were propounding all kinds of conceivable (and now-discredited) conspiracy theories about financial impropriety related to the AW-101 procurement process. Needless to say, I will doggedly continue with my efforts to expose the convulated illogical mumbo-jumbo of such ‘desi’ journalists who most definitely are not India’s wellwishers.

Spotlight On INS Kamorta

(Project 28) ASW Corvette

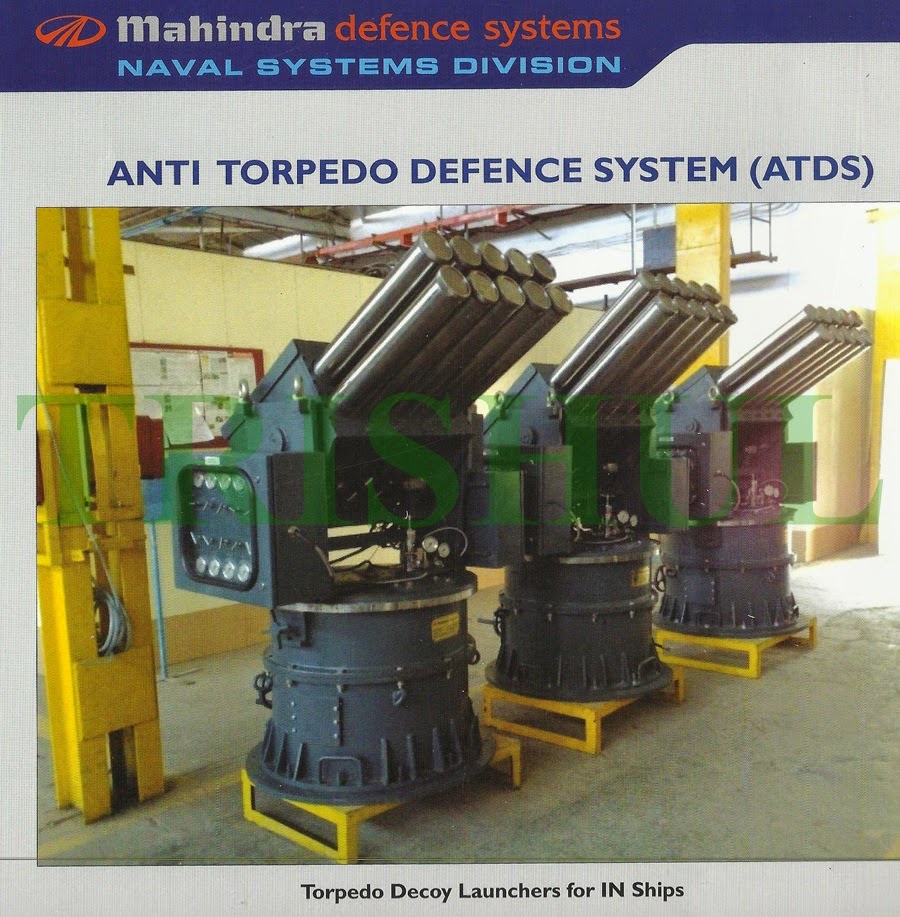

All four Project 28 ASW corvettes will have on board the RAFAEL-suppliedC-Pearl EW system and ELTA’s ELK-7038 DF system—the same as those on board the Indian Navy’s six105-metre NOPVs now in delivery. The Lynx-U2 NGFS is licence-assembled by BEL and has been supplied by Oerlikon Contraves, which is now a part of Germany’s Rheinmetall.

Build-Qualities Of Submarines

↧

New Force Accretions Are Welcome, But There's More On The Waiting List-1

Before getting into the nitty-gritty of various procurement contracts that were green lighted since last December, it is necessary to clear the mis-conceptions created solely by the ‘desi’ journalists regarding the roles and functions of the Indian Defence Ministry’s (MoD) Defence Acquisition Council (DAC), headed by the Defence Minister/Raksha Mantri, and the Defence Procurement Board (DPB). The DAC’sfunctions include (i) in-principle approval of the 15-year Long-Term Integrated Perspective Plan (LTIPP) for the three armed services (ii) accord of Acceptance of Necessity to acquisition proposals that are prioritised by the HQ Integrated Defence Staff (HQ IDS); (iii)categorisation of the acquisition proposals relating to ‘Buy’, ‘Buy & Make’ and ‘Make’; (iv) issues relating to single-vendor clearance; (v)decision regarding direct/indirect industrial ‘offsets’ provisions in respect of acquisition proposals above Rs.300 crores; (vi) decisions regarding transfer of technology (ToT) under the ‘Buy & Make’ category of acquisition proposals; and (vii) authorisation and facilitation of field-trial evaluations either on a competitive basis or sole-source basis. It is ONLY AFTER the DAC authorises a procurement process to begin that each armed service HQ begins the process of preparing and then issuing global or restricted Requests for Proposals (RFP).

The DPB, on the other hand, is the body that oversees all activities related to procurement on capital account in the MoD’s Department of Defence flowing out of the ‘Buy’ and ‘Buy & Make’ decisions of the DAC. It functions mainly as a coordinating, supervising and monitoring body for the procurement process undertaken by the Acquisitions Wing of the Department of Defence for the ‘Buy’ and ‘Buy & Make’ categories. In this process, it has the responsibility of approving the Annual Acquisitions Plans for the three armed services. It essentially accords approvals to all major projects which are beyond the powers of the Raksha Mantri (Defence Minister) and require the approval of the Cabinet Committee on National Security (CCNS) or the Union Ministry of Finance. The Defence Secretary is the Chairman of the DPB and its members include representatives from the various Departments in the MoD, the three armed services, and the Chief of IDS. The Member Secretary is the Financial Adviser in the Acquisition Wing of the Department of Defence.

Let’s now proceed to the various approvals accorded for procurement. It was on December 23, 2013 that the DPB cleared procurement proposals worth Rs.16,000 crore (US$2.75 billion) that included 1) re-lifing of some 400 Israel Aerospace Industries-supplied Barak-1 missiles that were acquired for the Indian Navy (IN) between the years 2000 and 2005 (on October 23, 1999the 268.63 million/Rs.5.8 billion contract for procuring seven Barak-1 point-defence missile systems or or PDMS, including 224 missile rounds worth $69.13 million and 14 EL/M-2221 STGR combined fire-control radars/optronic fire directors was inked and these were subsequently installed on the aircraft carrier INS Viraat, three Project 15 DDGs and three Project 16A FFGs Brahmaputra, Beas and Betwa. By late 2003 the MoD inked a $100 million contract to acquire another four Barak-1 PDMS to be installed on three Project 17 FFGs and on INS Ran Vijay, a Project 61ME/Kashin 2-class DDG.); 2) procurement of seven new-build Barak-1 PMDS suites for the three Barch-2 Project 1135.6 FFGs and the four Project 28 ASW corvettes; 3) opening of competitive bids for supplying two deep-submergence rescue vessels (DSRV) worth Rs.1,500 crore ($258.62 million); and 4) placing orders for two Goa Shipyard Ltd-designed 75-metre naval offshore patrol vessels (NOPV), which are to be delivered to the Sri Lanka Navy as part of a financial assistance package from India to Sri Lanka. Barring the DSRV contract, all of the above-mentioned contracts have since been inked and orders placed.

This was followed in January 2014 by the DPB’s approval for inking a contract worth $300 million Rs.1,740 crores for procuring 98 Whitehead Alenia Sistemi Subacquei-built Black Shark heavyweight torpedoes for for the IN’s six Scorpene SSKs that are due for delivery between September 2016 and late 2019. This contract, however, has yet to be inked. After orders are placed, the first 20 Black Sharks will be delivered directly by WASS, while the MoD-owned Bharat Dynamics Ltd will licence-assemble the rest from WASS-supplied completely knocked-down kits.

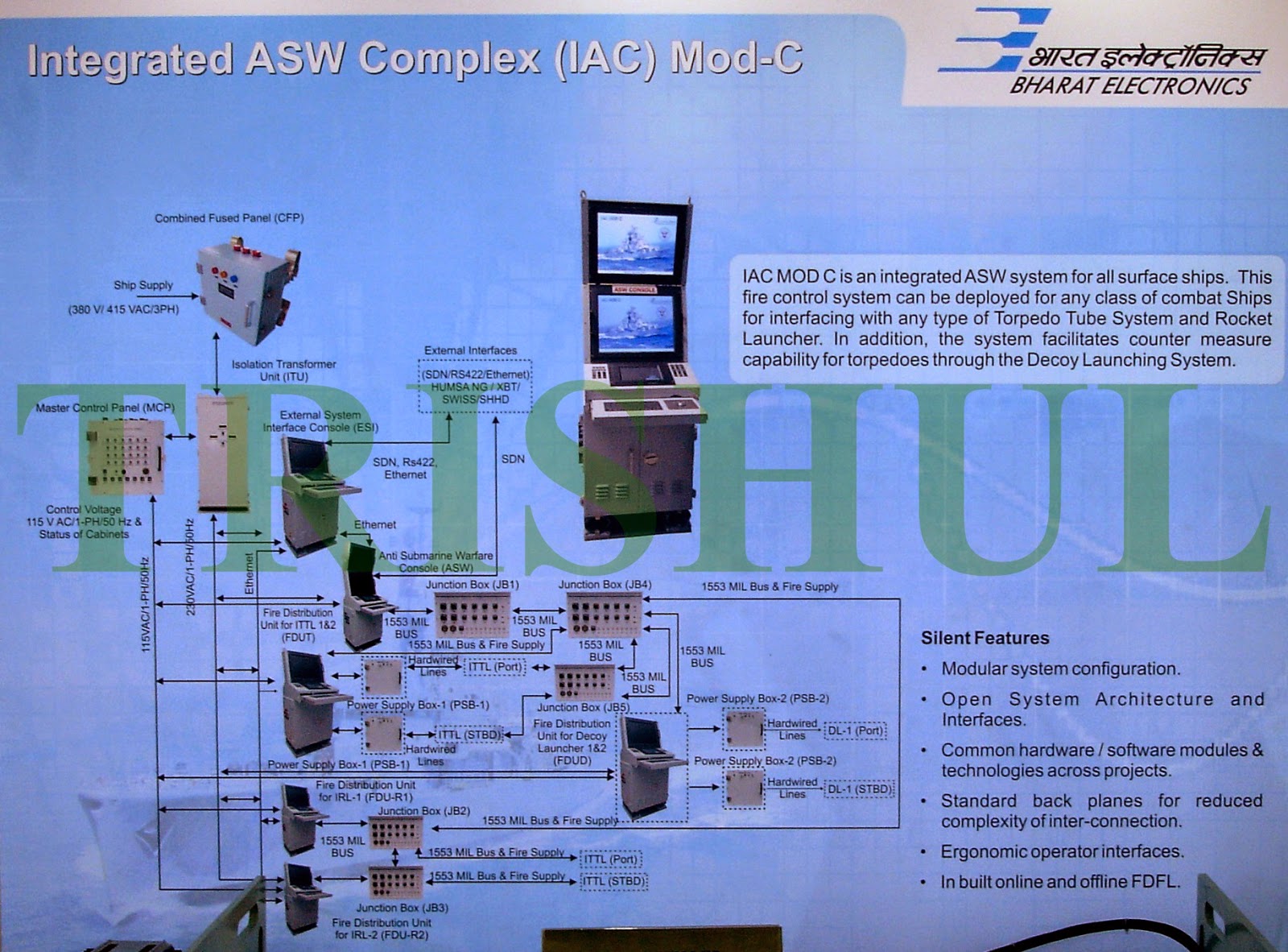

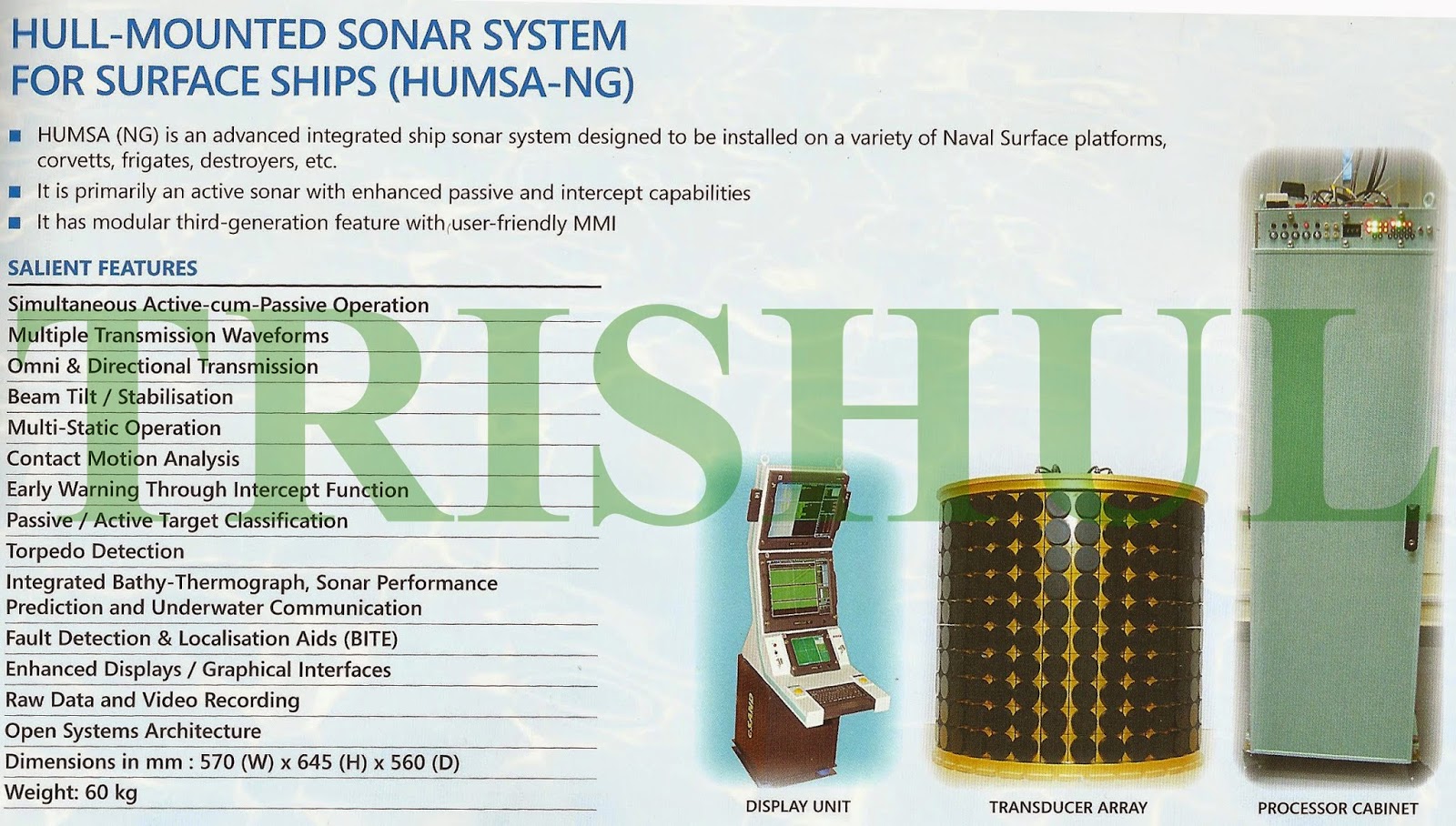

On August 30, 2014, the DPB cleared for contract signature (subject to the mandatory CCNS approval) the following: 1)Rs.4,800 crores ($827.5 million) for medium-refits of two Type 877EKM SSKs and a service life-extension programme (SLEP) for one Type 877EKM SSK, plus the mid-life upgrade of the three Project 15 DDGs; 2)Rs.1,770 crores ($305.17 million) for procuring six Atlas Elektronik-built ACTAS ultra-low-frequency towed-array sonars for the three Project 15 DDGs and three Batch-1 Project 1135.6 FFGs, procuring 10 HUMSA-NG hull-/bow-mounted panoramic sonar suites for the three Project 15 DDGs, four Project 15B DDGs and three Project 16A FFGs, and procuring traffic collision avoidance system (TCAS-2) retrofit kits for all fixed-wing turboprop aircraft of the IN; 3) Rs.6,800 crores ($1.172 billion) for procuring 118 Arjun Mk1A MBTs along with related mobile field workshops, a Base Repair Workshop, a platoon gunnery simulator, plus ammunition stocks; 4) Rs.900 crores ($155.17 million) for TAC4G broadband communications networks from Israel Aerospace Industries for the Indian Army’s Tezpur-based IV Corps, Dimapur-based III Corps and Leh-based XIV Corps; 5)22 Boeing-built AH-64D Longbow Apache attack helicopters plus related equipment and services, all collectively valued at $1.4 billion (Rs.8,120 crores), plus 15 Boeing-built CH-47F Chinook heavylift utility helicopters worth$1.4 billion (Rs.8,120 crores); and 6)16 Sikorsky S-70B Seahawk ten-tonne NMRHs worth Rs.1,800 crores ($310.34 million). Also cleared for procurement on a fast-track basis were all-terrain weapon locating radars and long-range man-portable thermal imagers for the Border Security Force (BSF), as well as close to 200 8 x 8 heavy-duty left-hand drive trucks (to be delivered by BEML-TATRA Sipox UK) for housing Pinaka-1 MBRLs their command posts, ammunition resupply vehicles and mobile field repair workshops, as well as 29 DRDO-developed/Bharat Electronics Ltd-built ‘Swathi’ weapon locating radars and their related field repair workshops. Total outstanding requirement for such trucks as of September 2010 was 1,676 units.

Lastly, funds were released for the IN’s existing Dwarka-2 forward operating base in Porbandar to be expanded into a permanent naval base that will be spread over 500 acres and will host both warships and submarines. It will be known as INS Sardar Patel.

On that very day, the DAC authorised the MoD’s DRDO to begin the process of prototype development of the Arjun Catapult. Subject to successful user-trials being concluded by early 2016, 40 such units will be ordered at a cost of Rs.820 crores ($141.37 million, or $3.53 million per unit).

As far as the present-day state of the eight surviving Type 877EKM SSKs goes, Russia’s Rubin Central Design Bureau for Marine Engineering had confirmed to me last March that the authorised total technical service life of each such SSK is not 20 years or 26 years as has been claimed by several retired IN officials over the past few days, but 35 years. Furthermore, each such SSK undergoes only one medium refit (inclusive of a mid-life upgrade) once after completing 13 years of service, and on its 26th year in service, it will undergo a service life-extension programme (SLEP) or a long-refit (inclusive of further upgrades) so that it will remain in service for a total period of 35 years. As part of the SLEP for the remaining eight Type 877EKM SSKs, the IN in future plans to equip them with thin-line towed-array sonars as well as new-generation optronic periscopes. Thus, while the IN will by 2018 be able to muster eight Project 08773 SSKs and retain the last of them in service will 2027.

The Severodvnsk-based Zvezdochka State Machine-Building Enterprise has to date upgraded five of the eight Type 877EKM SSKs to Project 08773 standard at an aggregate cost of Rs1,560 crore (or an average of US$156 million per unit):

* INS Sindhughosh S-55, whose keel was laid on May 29, 1983, was launched on July 29, 1985 and was commissioned on November 25, 1985 and it was subjected to a medium-refit and was also upgraded to Project 08773 standard between 2002 and 2005.

* INS Sindhudhvaj S-56, whose keel was laid on April 1, 1986, was launched on July 27, 1986 and was commissioned on November 25, 1986.

* INS Sindhuraj S-57, which was commissioned on September 2, 1987, was subjected to a medium-refit and was also upgraded to Project 08773 standard between 1999 and 2001.

* INS Sindhuvir S-58, which was commissioned on December 25, 1987, was subjected to a medium-refit and was also upgraded to Project 08773 standard between 1997 and 1999.

* INS Sindhuratna S-59, which was commissioned on August 14, 1988, was subjected to a medium-refit and was also upgraded to Project 08773 standard between 2001 and 2003.

* INS Sindhukesari S-60, which was commissioned on October 29, 1988, was subjected to a medium-refit and was also upgraded to Project 08773 standard between 1999 and 2001.

* INS Sindhukirti S-61, which was commissioned on October 30, 1989, has been declared as a writeoff.

* INS Sindhuvijay S-62, which was commissioned on October 27, 1990, was subjected to a medium-refit and was also upgraded to Project 08773 standard between 2005 and 2007.

* INS Sindhurakshak S-63, which was commissioned on October 2, 1997, was subjected to a medium-refit and was also upgraded to Project 08773 standard between August 2010 and January 2013.

Next in line for a medium-refit and upgrading to Project 08773 standard is INS Sindhushastra S-64, which was commissioned on May 16, 2000. This will be followed by the medium-refit of INS Sindhudhvaj S-56.--all this being confirmed by the MoD way back in September 2013. Contracts for both medium-refits will be concluded between 2015 and 2019. INS Sindukesari S-60 will soon proceed to Severodvnsk for its final SLEP.

Project 75 Conundrum

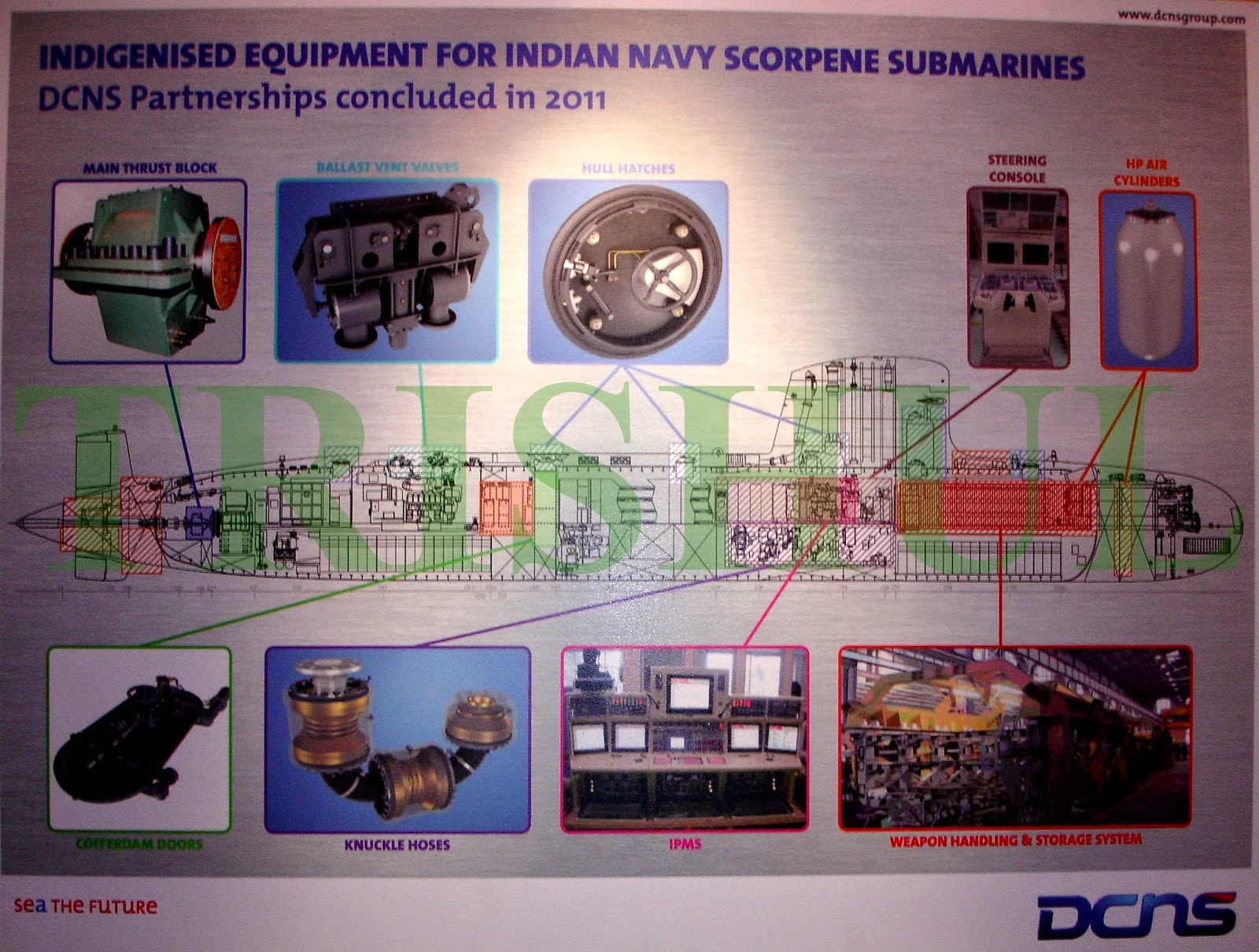

ARMARIS’ then Chairman Peter Legros had on July 10, 2005 confirmed that a revised package was being finalised under which an adjustable price mechanism (known as REM) to offset the cost escalations caused by delays in finalisation of the Project 75 contract (involving the licenced-construction of six single-hulled 1,565-tonne CM-2000 Scorpene diesel-electric submarines—all to be assembled by the MoD-owned Mazagon Docks Ltd, or MDL) would be arrived at by the MoD’s Price Negotiations Committee in the near future. On October 6, 2005 the contract for was finally inked, with the then French Ambassador in New Delhi Dominique Girard and the MoD’s Additional Secretary (Acquisitions) D Banerjee signing on the contract worth Rs 18,798 crore. Of this amount, Rs.2,700 crores (400 million Euros) was set aside for MDL to place orders with both foreign OEMs and local vendors for materials (all grouped under the category MDL-Procured Materials, or MPM) like 80 HLES high-yield steel steel (coming from ArcelorMittal), pipings, shaftings and valves. The contract also stated that the MoD had the option of procuring another four MDL-built Scorpene SSKs between 2015 and 2020—these being the AM-2000 version of the Scorpene and equipped with an AIP plug-in module. Metal-cutting for the first CM-2000 SSK began on May 25, 2007, and keel-laying of the first three SSKs took place in December 2006, December 2007 and August 2008, respectively. By late 2009, however, it had become evident that the various India-based industrial vendors that had been contracted for supplying the pipings, shaftings and valves had failed to comply with the stringent build-specifications of both DCNS of France and Spain’s Navantia (which together had formed the ARMARIS consortium). In fact, both the IN and MDL had warned the MoD about such an eventuality and had suggested way back in mid-2005 that of the six CM-2000 SSKs, the first two ought to be built at DCNS’ Cherbourg-based shipyard (if this was done, then the IN would have received its first two CM-2000s by late 2012) and during their manufacturing stages, the various contracted Indian industrial vendors would be mentored by their French and Spanish counterparts to attain the required degree of production competencies, thereby ensuring consistency in QC and QA levels once MDL began licence-building the remaining four Scorpene SSKs. However, since this did not happen, as predicted, the Indian vendors failed to produce components that were compliant with OEM-mandated specifications and this, consequently forced MDL to exercise the only option then left on the table: place orders with France-based and Spain-based OEMs for supplying such components at an extra cost of Rs.4,700 crores (700 million Euros). Consequently, the total cost of Project 75 was hiked to Rs.23,562 crores in February 2010, along with revisions in delivery schedules. New indents for MPMs were placed between mid-2010 and November 2012. On top of all this, internal project mismanagement by MDL created additional complications. For instance, although four batches of a total of six CD-based Transfer of Design Data (TDD) packages had reached MDL by the first quarter of 2013, they could not even be opened because the CAD-5 software to run the CDs had not been acquired by MDL. Similarly, though DCNS had advised MDL in 2006 to buy a 2000-tonne press for bending the thick steel plates supplied byArcelorMittal, MDL acquired it only in 2011. By then, the contract for bending the steel plates had been outsourced to Pipavav Defence & Offshore Engineering Ltd. The press now lies idle in MDL, with no steel to press since all the hulls have already been made. MDL had also signed a 65 million Euros contract with both DCNS and Navantia for deputing an ‘Advising & Overseeing Team’, and ended on March 15, 2013 and this contract was renewed only late last year. The first Scorpene SSK is now scheduled for delivery in September 2016 (instead of December 2012 as originally planned), and thereafter, one each every nine months through to May 2019.

The above shameful saga only raises some pertinent questions that no one has bothered to ask so far: why did the MoD and its Department of Defence Production & Supplies, along woth the Govt of India’s Department of Industrial Policy and Promotion (DIPP) decide to licence-build all six Scorpene CM-2000 SSKs despite the grave reservations expressed by both IN HQ and MDL? And did anyone or a group of officials making up the decision-making loop become direct or indirect financial beneficiaries through such willful criminal negligence at the cost of the Indian exchequer?

This then brings us to the option for procuring the four AM-2000 SSKs. While the performance parameters of both the CM-2000 and AM-2000 variants remain the same, the length of the AM-2000 increases to 70 metres and its submerged displacement is 1,870 tonnes, against the 61.7 metres and 1,565 tonnes of the CM2000. Both SSK variants will have a crew complement of 31 (with a standard watch-team of nine) and endurance of 50 days. The AM-2000’s hull too will be built with HLES-80 high-yield stress-specific steel, which will allow the SSK to reach diving depths of up to 300 metres (1,150 feet) and achieve an average of 240 days at sea, per year, per submarine. The AM-2000, just like the IN’s six CM-2000s, will also feature a connection point for allowing a DSRV to dock during collective crew-rescue operations.

Though the DRDO’s Ambarnath-based Naval Materials Research Laboratory (NMRL), along with the Kochi-based Naval Physical and Oceanographic Laboratory (NPOL), have since 2002 been trying to developing an on-shore fuel cell-based air-independent propulsion (AIP) system that will enable an SSK to stay submerged continuously for about 25 days, till to date, no significant R & D breakthroughs have been achieved nor are they expected to be achieved in the latter half of the decade. Apart from the NMRL and NPOL, other DRDO laboratories and industrial entities that are involved with this R & D venture are Larsen & Toubro, THERMAX, IOCL, TEXOL, Indian Institute of Petroleum, AKSA, CEEFES, C-DAC, DIGITRONICS, NSTL, RCI, ROLTA and MDL. This then leaves the IN with only two AIP options: either go for the DCNS-developed MESMA (Module d’Energie Sous-Marine Autonome) system, or opt for the Stirling Engine. In MESMA, ethanol and liquid oxygen are mixed in a high-pressure burner to a temperature of 700 degrees Celsius, which acts as a heat source for a primary water-loop, which is pressurised at 60 bar, thereby allowing operations to full diving depth (a bar is a measure of pressure roughly equivalent to one atmosphere; at the sea surface the pressure is 1 bar, at 10 metres it is 2 bar, at 20 metres it is 3 bar, at 100 metres it is about 10 bar and at 600 metres it is 60 bar). The primary loop passes through a steam generator. The steam, which is greater than 20 bar and 500 degrees Celsius, spins a turbine attached to an alternator. The alternator charges the SSK’s battery. The MESMA AIP on the three Agosta 90B SSKs of the Pakistan Navy is capable of producing 200kW of energy, which provides enough energy to for a light battery-charging rate when the SSK is cruising at 6 Knots. Newer versions of MESMA use diesel instead of ethanol that, like the Stirling Engine, limits the additional AIP fuel supply to just liquid oxygen.

The Stirling-based AIP is a closed-cycle engine that uses helium as the working fluid. Diesel and liquid oxygen are mixed in a high-temperature burner to a temperature of 750 degrees Celsius, which acts as a heat source for an enclosed quantity of helium. The helium is driven through a repeating sequence of thermodynamic changes. By expanding the helium against a piston and then drawing it into a separate cooling chamber for subsequent compression, the heat from the external combustion of diesel and oxygen can be converted into work that can then be turned into electrical energy by a DC generator. The DC generator charges the battery. Gases from the process are mixed with cooling water in a special carbon dioxide dissolver and discharged into the sea. This AIP uses less pressure than a MESMA, operating at 20 bar. Each Stirling Engine is capable of producing 75kW of energy, with two or more installed on each SSK.

The Stirling-based AIP is a closed-cycle engine that uses helium as the working fluid. Diesel and liquid oxygen are mixed in a high-temperature burner to a temperature of 750 degrees Celsius, which acts as a heat source for an enclosed quantity of helium. The helium is driven through a repeating sequence of thermodynamic changes. By expanding the helium against a piston and then drawing it into a separate cooling chamber for subsequent compression, the heat from the external combustion of diesel and oxygen can be converted into work that can then be turned into electrical energy by a DC generator. The DC generator charges the battery. Gases from the process are mixed with cooling water in a special carbon dioxide dissolver and discharged into the sea. This AIP uses less pressure than a MESMA, operating at 20 bar. Each Stirling Engine is capable of producing 75kW of energy, with two or more installed on each SSK.

Blowing The Lid Off The INS Sindhukirti Saga

For far too long, the ‘desi’ band of journalists covering national security issues has consistently alleged that almost all foreign OEMs—and especially those hailing from Russia—have never lost any opportunity to take India for a ride, that India has always been at the receiving end of their ‘devious’ marketing efforts, and consequently, India can never depend upon such OEMs when it comes to the crunch. The most recent example of ‘yellow journalism’ has appeared here:

News-reports like the one highlighted above always inevitably contain only selective facts, which in turn tell only one side of the story, and consequently, the truth always becomes the first casualty. So what exactly is the hitherto-untold saga of the INS Sindhukirti? To get to the bottom of matters, we need to go back to the year 2004 when the IN has headed by Admiral Madhvendra Singh(he was the Chief of the Naval Staff between December 29, 2001 and July 31, 2004). INS Sindhukirti had by then been in service for 15 years and was due for its mid-life medium-refit—a job that could be done only at a Russian shipyard—since neither the USSR nor Russia had ever allowed/authorised any other shipyard abroad (be in it India or China) to undertake such jobs.

It was at this time that Chennai-based The India Cements Ltd’s N Srinivasan (presently its Vice Chairman & Managing Director and also Chairman of the ICC) teamed up with a former IN submariner by the name of Commodore S Shekhar (see his bio-data at: http://www.globalsar.com.my/shekhar.html), who is the Promoter and Managing Director of JMPS Sanjivini Consultants (Pvt) Ltd, for exploring ways and means of entering India’s market for submarine MRO-related businesses. Together, Srinivasan and Shekhar did a detailed feasibility study on the prospects of conducting in-country medium-refits of the IN’s fleet of Type 877EKM SSKs in cooperation with Russia-based OEMs. The feasibility study, conducted with the assistance of Russia’s Rosoboronexport State Corp, was next taken to the Chairman & Managing Director (CMD) of state-owned and Vizag-based Hindustan Shipyard Ltd (HSL), Rear Admiral (Ret’d) Ajit Tewari, who was previously the Assistant Chief of Naval Staff (P & P) at Naval HQ and after his retirement, became HSL’s CMD on February, 3, 2004. This where the scene gets murky, since Naval HQ sometime in mid-2004 authorised HSL (which came under the MoD’s administrative control only on February 8, 2008) to begin work on INS Sindhukirti’s medium-refit (with Srinivasan and Shekhar reportedly acting as project consultants for HSL) despite the fact that HSL had by then not inked any kind of military-industrial agreement with Rosoboronexport State Corp (consequently, HSL at that time was not authorised by either the Govt of the Russian Federation or any Russian OEM for undertaking any kind of medium-refit-related activity on any Type 877EKM SSK).

It was only on October 3, 2006 that Rosoboronexport State Corp inked a Rs.650 crores contract with HSL for rendering industrial-cum-technological assistance to HSL for undertaking the INS Sindhukirti’s medium-refit-cum-upgrade—a task that was originally due for completion by 2010. Rosoboronexport State Corp in turn signed a back-to-back contract with the Severodvnsk-based Zvezdochka State Machine-Building Enterprise, which became HSL’s principal industrial partner for executing the INS Sindhukirti’s medium-refit-cum-upgrade. Zvezdochka subsequently began materials supplies as well as turn-key activities that included: completion of entire degutting in May 2007, completion of blasting on the entire hull structure for defect survey in February 2008, removal of hard-patches from all six compartments, installation and commissioning of two pipe-bending machines at HSL, and qualifying and type-certifying HSL’s welders to take up repairs on INS Sindhukirti’s hull structures. And by May 2008, Zvezdochka had delivered to HSL all technical/engineering documentation that was required for undertaking the medium-refit-cum-upgrade.

The question that then arises is, why will INS Sindhukirti be delivered to the IN only in March 2015, when Zvezdochka takes between 24 and 28 months to refit-cum-upgrade a Type 877EKM SSK? The answer is elementary: it is all about skilled human resource mobilisation. Zvezdochka typically employs more than 200 personnel in three shifts to complete the job in two years, while HSL until late 2008 could mobilise only 50 workers. Furthermore, HSL bagged the contract for INS Sindhukirti’s medium- refit-cum-upgrade at a time when highly skilled human resources like welders were in high demand at the nearby Ship Building Centre (SBC), which had then been leased by the MoD to Larsen & Toubro (L & T) for undertaking final assembly of the S-2/Arihant SSBN’s hull superstructure. L & T, which began shipping the S-2/Arihant’s hull-rings (fabricated at Hazira) and internal bulkheads and fitments (fabricated at Powai), literally poached all of HSL’s pool of skilled human resources by offering them much higher salaries and related perks—all of which left HSL high-and-dry. HSL consequently had no other option but to recruit new personnel and with Zvezdochka’s assistance, train them from scratch until they could acquire a credible degree of job proficiency—a task that easily consumed almost four years. And that’s the reason why INS Sindhukirti’s medium-refit-cum-upgrade could not be completed by 2010 as originally scheduled.

(to be concluded)

↧

India-PRC Boundary Dispute Decoded

India’s First catastrophic Error: Failing to detail her territorial boundary claims in a consistent manner between 1950 and 1954 and issuing conflicting political maps (below):

As a result, the PRC was free to make territorial claims, especially in the Western Sector (below) and also secure the Aksai Chin area uncontested and without any military opposition.

India’s second catastrophic error: Initiating the ‘Forward Policy’ (below) under which logistically unsustainable and militarily indefensible forward military observation posts and pickets were set up (below):

And as a result of all this...

This then brings us to the present-day ground situation:

↧

MAKS 2015 Show Report-1: Russia Is Stuck Between A Rock And A Hard Case

Moscow today is trying to deal with several crises at the same time. Firstly, there is the severe economic crisis brought on by the collapse in the price of crude oil and the continuing bite of Western economic sanctions brought on by the Russian annexation of Crimea and Russia’s support of the civil war in eastern Ukraine. With the Iran nuclear deal moving forward, it is highly likely that large amounts of Iranian crude oil will come on the market in the coming years. This in turn has caused futures contracts for crude oil to plunge, damaging Russia's ability to meet spending targets for its ambitious military goals. Moscow’s refusal to diversify its economy in the heady days of US$100 per barrel of crude oil is now coming back to haunt it. The war in eastern Ukraine shows no signs of stabilising anytime soon, either. In fact, the NATO alliance is claiming that upwards of 50,000 Russian troops are mobilised along the border with Ukraine. The Kremlin will face tough decisions in the near-term as social spending has already been cut dramatically and the threat of social unrest due to high military spending ($18 billion in 2015, or 4.2% of Russia’s GDP) in the face of further social security cutbacks is very real.

Secondly, Russia’s population is declining in quantitative terms, which in turn is posing a severe strain on the availability of skilled human resources. And this is happening at a time when the Kremlin may well be required to launch low-intensity military operations against Estonia and Latvia in order to secure the interests of the Russian-speaking disenfranchised citizens of these two countries. Russia’s previous National Security Doctrine, which was signed into law in 2009 by then-President Dmitry Medvedev, has been superceded by the current military doctrine that President Vladimir Putin signed into law in December 26, 2014, which cited “NATO’s military buildup” as a key driver for the changes.

The new doctrine, beyond explicitly stating that NATO’s expansion is the main external threat facing Moscow, calls for reinforcing three geopolitical fronts that Russia sees as part of its existential security. In the coming years Russia will focus considerable resources in developing and maintaining a strong military presence in the Arctic, the recently annexed Crimean peninsula, and the Russian exclave of Kaliningrad on the Baltic Sea.Each of these three regions is vital for Russia’s goal of checking NATO expansion, while simultaneously maintaining access to potential natural resources, as in the case of the Arctic, and warm water shipping routes.Russia’s military expansion in the Arctic has been a major goal for Putin for much of the past decade. The new military doctrine officially puts special focus on the region and advocates a greater Russian role in the region to help ensure access to potential energy resources on the Arctic seabed against possible Danish, Norwegian, Canadian, and US claims. The US estimates that upwards of 15% of the world’s remaining oil, 30% of its natural gas, and 20% of its liquefied natural gas are stored in the Arctic sea bed. Moscow has undertaken a construction blitz across the Arctic in a bid to ensure that it remains the unchallenged military power in the region. It is presently building 10 Arctic search-and-rescue stations, 16 deepwater ports, 13 airfields, and ten airspace surveillance radar stations across its Arctic coast. Simultaneously, Moscow has created a Joint Strategic Command North (JSCN) from components of the Russian Navy’s Northern Fleet in order to maintain a permanent military presence in the region. It is likely that this command will ultimately become a fifth military district. Bottomline: Russia’s strategic focus in the years ahead will continue to be Euro-centric, and not not Eurasia-centric.

Thirdly, even though Russia is already the world’s second-biggest arms exporter (accounting for 27% of the global export market, with the US staying ahead with 31% market-share, and being followed by China with 5%, Germany with 5%, France with 5% and the UK with 4%), it is facing increasingly tough competition from the People’s Republic of China (PRC) with each passing day—especially in South Asia, the Middle East and Central America.

Fourthly, the PRC’s weapons manufacturers have succeeded to a large extent in back-engineering several weapons, sensors and fire-control systems that were on the drawing boards during the last years of the Soviet era, and whose production-engineering data were easily available from various countries of the Commonwealth of Independent States (CIS). Since 1991, the PRC had struck several military-industrial partnerships with several CIS-based original equipment manufacturers (OEM), especially in Ukraine, Belarus and Kyrgyzstan, for the purpose of obtaining critical research and development (R & D) inputs that are required for developing and producing new-generation weapon systems for the People’s Liberation Army (PLA). Consequently, Ukraine’s total arms exports grew steadily, from $20 million in 1994 to $600 million in 1997 and $1.5 billion in 2001. In 2002 the Industrial Policy Ministry of Ukraine and the PRC’s Commission for Science, Technology and Industry for National Defense (COSTIND) signed a protocol on cooperation in the military-industrial arena. In that same year, Ukraine became the world’s fourth-largest weapons exporter and sold weapons and military technologies to Beijing worth $700 million, which accounted for 31% of Ukrainian exports that year. In 2011, 43% of Ukraine-built weapons were sold to the PRC, while in 2013 Ukraine became the PRC’s second-largest trade partner in the CIS, while the PLA became Ukraine’s biggest military customer in Asia.

Since 2002, the following Ukraine-based firms/enterprises/R & D institutes have had military-industrial partnerships with the PRC: Aerotechnica-MLT Ltd,ARSENAL Central Design Bureau State Enterprise, ARSENAL State Enterprise Plant, AVIAKONTROL Joint Stock Company (JSC), AVIONIKA Ltd, BURAN State Enterprise Research Institute, CHERNOMOSUDOPROEKT, Chernomorsky Shipbuilding (formerly the Nikolayev South Shipyard Soviet Shipyard No. 444), Engine Design Bureau of Kharkiv (EDBK),FEODOSYA State-Owned Optic Plant, ISKRA Ltd, Ivchenko-Progress OKB, Kharkiv Morozov Machine Building Design Bureau,KVANT Research Institute, Kyiv Plant Radar JSC, LUCH KYIV State Design Bureau, LVIV State Plant, Motor Sich JSC,MORYE Feodosya Shipbuilding Company, ORDZHONIKIDZE Sevastopol Marine Plant, PROGRESS Zaporozhye Machine-Building Design Bureau,RADIONIX Ltd, Radioizmeritel Plant, Scientific Research Institute for Aeroelastic Systems, Scientific and Technical Enterprise Electronprylad JSC,State Enterprise Malyshev Plant, UkroboronpromJSC, Ukrspetsexport JSC, UkrspetstechnikaJSC, YUZHMASH Southern Machine Building Plant Association, VIZAR ZHULIANY Machine-Building Plant, and Zorya–Mashproekt State Enterprise.

Ukrainian officials in August 2001 had conspired in the illegal sale of 12 Ukraine-owned Kh-55 strategic cruise missiles—six each to China and Iran (known locally as the Soumar GLCM), plus four Kolchuga passive surveillance systems to the PRC.Also smuggled out of Kiev by August 2001 were detailed production engineering data packages of a long-range land-attack cruise missile (LACM) called Korshun, which had by then been developed by Ukraine’s Dnipropetrovsk-based Yuzhnoye State Design Bureau, with production tooling being built by the Yuzhnoye Machine-Building Production Association, or Yuzhmash. The Korshun’s powerplant was a redesigned RD95-300 turbofan that bore a strong resemblance to the 36MT engine developed by Russia’s NPO Saturn. This turbofan was subsequently re-engineered in the PRC by its 624 Engine Design Institute, or the China Gas Turbine Establishment (GTE), and its related Chengdu Engine Group. Dimensions of the Korshun, which was identical to the Raduga-developed Kh-65SE LACM (first displayed in August 1992), included a wingspan of 3.1 metres, length of 6.3 metres, diameter of 0.514 metres, and a mass of 1,090kg.

Range of the LACM was then claimed to be 600km when carrying a 500kg warhead. By late 2003, the General Armaments Dept of COSTIND, the China Aerospace Science and Technology Corp’s (CASC) 3rd Aerospace Academy (also known as China Haiying Electro-Mechanical Technology Academy or CHETA, or the 066 Base in Hubei) and 8359 Research Institute had, along with the Beijing University for Aeronautics & Astronautics, Shanghai Jiaotong University, China State Electronics Systems Engineering Corp, Sichuan Aerospace Industry Corp and the Tianjin Institute for Power Sources had completed fabrication of the first six prototypes of the 800km-range Chang Jian CJ-10 LACM (a direct copy of the Korshun), and on August 10, 2004 the first test-firings were conducted at an instrumented offshore range in the Bohai Sea. Its configuration features a cylindrical body with two retractable wings, four non-retractable tailfins as well as a retractable engine inlet. The CJ-10 made its first public appearance during the October 1 military parade in 2009. In early 2005, flight-tests of another variant of the CJ-10, having a range of 1,200km, were carried out. The CJ-10 has since been deployed by China with both conventional HE/FAE and tactical low-yield nuclear warheads, with the latter developed by a consortium of China’s 7th Research and Design Institute, owned by the China National Nuclear Corp, China Metallurgical Equipment Corp (CMEC) and China Southwest Institute for Nuclear & Fluid Physics.

CASC’s 3rd Academy’s Beijing Xinghang Electromechanical Equipment Factory (159 Factory) is the final assembly facility for the CJ-10, while Beijing Hangxing Machine Building Factory (239 Factory) and the Xinxin Factory in Shanghai produce the various on-board components of the CJ-10. The LACM and its ALCM variant carries a range of different 770lb or 1,100lb warheads. The GLCM variant of the CJ-10 has a length of 7.0 metres, launch mass of 1,350kg, warhead mass of 300kg, cruise speed of 0.9 Mach. Thus far, the PLAAF has operationalised 20 H-6K bombers capable of launching the CJ-10’s ALCM variant. There are presently three operational, road-mobile, CJ-10 Brigades: the 821 Brigade, 96215 Unit in Liuzhou, Guangxi Province; the 824 Brigade, 96317 Unit in Dongkou, Hunan Province; and a third Brigade in Jianshui, Yunnan Province

Another highly successful military-industrial partnership between the PRC and Ukraine concerns the PLA Navy’s Type 052C Luyang-class guided-missile destroyers (DDG). Each of these DDGs come equipped with six forward vertical launch stations (VLS) each containing six revolving long-range surface-to-air missile (LR-SAM) launchers (for 36 Hong Qi-16 LR-SAMs) located below the bridge and behind the main gun; and a rear VLS station equipped with 12 Hong Qi-16 LR-SAMs forward of the helicopter hangar. Thus, a total of 48 Hong Qi-16 LR-SAMs are carried on board. The two-stage HQ-16 LR-SAM is ‘cold-launched’ vertically from a tubular launcher. The missile’s first stage has a diameter of 700mm while the second stage has a diameter of 560mm. The total launch mass is 2 tonnes, while the missile’s length is 9 metres. It is armed with a 180kg HE fragmentation warhead and has a maximum speed of Mach 4.2. The HQ-16 has a slant range of 125km and a service ceiling of 30km. The missile’s proximity fuze has an effective range of 35 metres, which goes active when the missile is 35 metres away from its target. The HQ-16’s guidance mechanism comprises initial inertial navigation, radio command mid-course correction, and active terminal guidance. When in range for an effective lock-on with the on-board X-band monopulse radar, the terminal guidance phase, lasting 20km, gets underway. The HQ-16 has been developed to specifically counter incoming intermediate-range/tactical ballistic missiles and supersonic anti-ship cruise missiles, and is therefore not cost-effective if deployed to counter only manned combat aircraft. For naval target tracking and engagement, the Jiangsu Province-based Nanjing Research Institute of Electronic Technology (NRIET, but also more commonly known as the 14th Institute) has co-developed with Ukraine’s the KVANT Research Institute, the shipborne Type 346 S-band multi-function active phased-array radar with four antenna arrays, each of which has a maximum range of 150km, a maximum resolution of 0.5 metres, and can scan a 0-120-degree arc in azimuth and 0-90 degrees in elevation, with a peak power output of 1mWe. The HQ-16 LR-SAM itself is a re-engineered version of the Soviet-era 5V55R LR-SAM and Ukrainian companies that were consultants to the PRC for developing the HQ-16 and its land-based HQ-9 LR-SAM variant (the FD-2000 being its export variant and already sold to Uzbekistan and Turkmenistan) were YUZHMASH and the VIZAR ZHULIANY Machine-Building Plant.

Other naval products that have been co-developed by the PRC with Ukraine’s assistance include the Type 382 radar (originally the Fregat-M2EM), Type 344 radar (originally the Mineral-ME), Type 345 radar (originally MR-90)—all of which were re-engineered by the Nanjing Marine Radar Research Institute/No 724 Institute; the SUR-17/Type 517B air surveillance radar with Yagi antennathat was re-engineered by the Yangzhou Marine Electronic Instruments Research Institute/ No. 723 Institute; and the Type 344 multifunctional fire-control radar that was re-engineered by the Xi’an Research Institute of Navigation Technology (XRINT) No 20 Research Institute.The Type 344 (Mineral-ME) and Type 382 (Fregat-M2EM) radars are installed on board the PLA Navy’s Type 054A Jiankai-class guided-missile frigates, while the Type 346s are on the PLAN's Type 052C/D Luyang-class DDGs and on the aircraft carrier Liao Ning. In addition, a seabed-based SOSUS network, developed jointly by Ukraine and China, has been under installation along China's territorial waters since 2012.

The PLAN’s sole aircraft carrier Liao Ning too has been refitted and upgraded with Ukraine’s military-industrial help. In another development, the PRC’s Nanchang-based Hongdu Industrial Aviation Group (HAIG) inked a contract in 2009 with Ukrainian engine manufacturer Motor Sich for the supply AI-222-25F turbofans—each valued at $2 million—for its production-standard L-15 ‘Hunting Eagle’ lead-in fighter trainer (LIFT). The first tranche of 12 engines was delivered in 2011. The tandem-seat, twin-engined L-15, co-developed by HAIG and Russia’s Yakovlev OKB, made its maiden flight on March 13, 2006. The first L-15 prototype, powered by twin non-afterburning ZMKB-Progress (Lotarev) DV-2 engines, was rolled out on September 29, 2005. The third prototype, powered by twin DV-2F afterburning turbofans, first flew on May 10, 2008, and was powered by twin non-afterburning AI-222-25 turbofans. The fourth prototype first flew on June 8, 2009, and was powered by two afterburner-equipped AI-222K-25F turbofans. The sixth L-15 prototype, which was rolled out on August 15, 2010, features a stretched nose that can house a multi-mode fire-control radar, HOTAS controls, and improved glass cockpit avionics with three AMLCD-based multifunction displays. Powered by two AI-222K-25F turbofans delivering enough thrust for sustained supersonic flight, its maiden flight took place on October 26, 2010. It features a three-axis quadruplex fly-by-wire flight control system. The L-15 has a maximum takeoff weight of 9,500kg, maximum speed of Mach 1.4, maximum climb rate of 150 metres/second, load sustenance of +8g/-3g, service ceiling of 16,000 metres, loitering time of two hours, and a structural airframe life of 10,000 flight hours. Unit price quoted for the L-15 is US$16 million. The L-15 is likely to be procured in future by the air forces of China, Myanmar and Pakistan.

Ukraine has also sold the PRC four Project 1232.2 Zubr hovercraft at a cost of US$315 million. While the first two were built (and delivered on April 12, 2013) by the Crimea-based MORYE Feodosya Shipbuilding Company in Feodosiya (now in Russia-annexed Crimea), the latter two are now being licence-assembled at the China State Shipbuilding Corp-owned Huangpu Shipyard in Guangzhou under the supervision of Ukrainian technicians. Ukraine has also helped the PRC upgrade its fleet of Su-27SK heavy multi-role combat (H-MRCA) aircraft by supplying kits for upgraded N-001 mlti-mode airborne radars (from RADIONIX Ltd), OMUT internalu jammers for Shenyang J-11B H-MRCAs, as well as upgraded ZSh-7APN Sura-K helmet-mounted display systems (HMDS) and upgrade kits for the OEPS-27 infra-red search-and-track (IRST) sensors. In addition, Ukraine has also helped the Sichuan Changhong Electric Appliance Corp and its Luoyang Optical-Electronic Technology Development Centre (LOEC) to develop both an indigenous HMDS as well as the Hongguang-I IRST sensor for the Shenyang J-11B, Chengdu J-10B and Shenyang J-15 MRCAs.

Lastly, Ukraine in 2001 supplied the PRC’s 601 Research Institute at Shenyang with one Su-33 carrier-based H-MRCA prototype (the T-10K-3) along with related production-engineering data as well as the source-codes (crypto-keys) for the aircraft’s fly-by-wire flight-control systems and its digital databus. The T-10K-3 aircraft had made its maiden flight onFebruary 17, 1990 in the former USSR. Also sold by Ukraine were the production-licences for the LIMAN ground-radio jammers, mobile GPS jamming systems, and road-mobile troposcatter-based communications relay systems like the TS-504 and multi-point TS-510/GS-510 systems, which are re-engineered versions of Ukraine’s R-423-1 Brig-1 troposcatter system.

When it comes to military-industrial cooperation with Belarus, in 1998, in the Chinese city of Hubei in Siogan Province a joint assembly plant called ‘Sanjiang Volat Co Ltd’ for the production of multi-wheeled tractors and chassis for various purposes with capacity from 20 to 75 tonnes was established.The founders of the joint venture with a capital of 52.2 million Yuan were Minsk Wheel Tractor Plant (MWTP), with an authorised capital share of 30% and Sanjiang Aerospace Corp with the 70 % share. MWTP contributed technologies and accessories for building multi-wheeled heavy-duty vehicles.In accordance with the agreed-upon business statutes, in the first five years of operation 70 % of all components for the plant should have been delivered by MWTP. Subsequently, the share of Belarusian components was intended to be reduced to 30%. But the PRC, known for its outstanding talent for re-engineering, exceeded the plan, and now MWTP provides only the wheel-hubs. The production facilities of Sanjiang Volat Co Ltd are designed to produce 300 multi-axle vehicles per year to meet the needs of the defence, oil, construction, mining and forestry industries. The industrial partners have since September 2009 also created a joint production facility for hydro-mechanical transmission (HMT) of heavy-duty vehicles and wheeled tractors. This facility is known as the Wuhan Sanjiang Import & Export Company Ltd (WSIEC), a subsidiary of China Sanjiang Space Group (CSSG).

With Kyrgyzstan, the PRC has joined forces to develop an indigenous version of the VA-111 Shkval supercavitating rocket-propelled torpedo, which achieves a high velocity of 230mph (386kph). The Shkval is fired from the standard 533mm torpedo tube at a depth of up to 328 feet (100 metres). The torpedo exits the tube at 50 Knots (93kph) and then ignites the rocket motor, propelling the weapon to speeds four to five times faster than other conventional torpedoes. The weapon has an 80% kill probability at a range of 7,655 yards (7,000 metres). The torpedo is guided by an autopilot rather than by a homing head as on most torpedoes. Manufacturing know-how for the torpedo’s cruise-control sub-systems has been procured from Ukraine, while Kyrgyzstan’s Dastan Engineering JSC has supplied the autopilot’s manufacturing know-how to the PRC.

To Be Concluded

↧

↧

The IAF’s Perception Management Disconnect & Its Plans For TMD Network