Before getting into the nitty-gritty of various procurement contracts that were green lighted since last December, it is necessary to clear the mis-conceptions created solely by the ‘desi’ journalists regarding the roles and functions of the Indian Defence Ministry’s (MoD) Defence Acquisition Council (DAC), headed by the Defence Minister/Raksha Mantri, and the Defence Procurement Board (DPB). The DAC’sfunctions include (i) in-principle approval of the 15-year Long-Term Integrated Perspective Plan (LTIPP) for the three armed services (ii) accord of Acceptance of Necessity to acquisition proposals that are prioritised by the HQ Integrated Defence Staff (HQ IDS); (iii)categorisation of the acquisition proposals relating to ‘Buy’, ‘Buy & Make’ and ‘Make’; (iv) issues relating to single-vendor clearance; (v)decision regarding direct/indirect industrial ‘offsets’ provisions in respect of acquisition proposals above Rs.300 crores; (vi) decisions regarding transfer of technology (ToT) under the ‘Buy & Make’ category of acquisition proposals; and (vii) authorisation and facilitation of field-trial evaluations either on a competitive basis or sole-source basis. It is ONLY AFTER the DAC authorises a procurement process to begin that each armed service HQ begins the process of preparing and then issuing global or restricted Requests for Proposals (RFP).

![]()

The DPB, on the other hand, is the body that oversees all activities related to procurement on capital account in the MoD’s Department of Defence flowing out of the ‘Buy’ and ‘Buy & Make’ decisions of the DAC. It functions mainly as a coordinating, supervising and monitoring body for the procurement process undertaken by the Acquisitions Wing of the Department of Defence for the ‘Buy’ and ‘Buy & Make’ categories. In this process, it has the responsibility of approving the Annual Acquisitions Plans for the three armed services. It essentially accords approvals to all major projects which are beyond the powers of the Raksha Mantri (Defence Minister) and require the approval of the Cabinet Committee on National Security (CCNS) or the Union Ministry of Finance. The Defence Secretary is the Chairman of the DPB and its members include representatives from the various Departments in the MoD, the three armed services, and the Chief of IDS. The Member Secretary is the Financial Adviser in the Acquisition Wing of the Department of Defence.

![]()

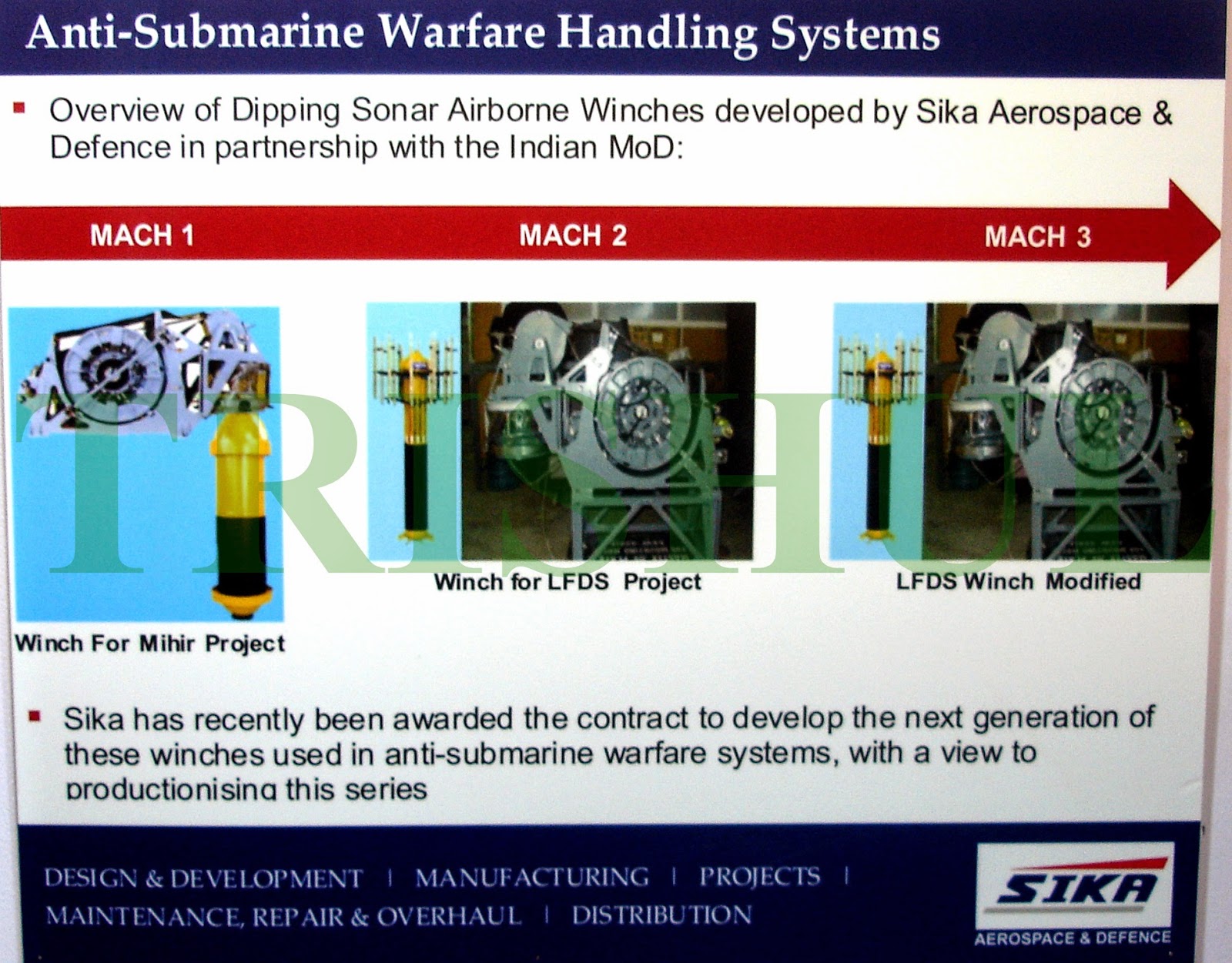

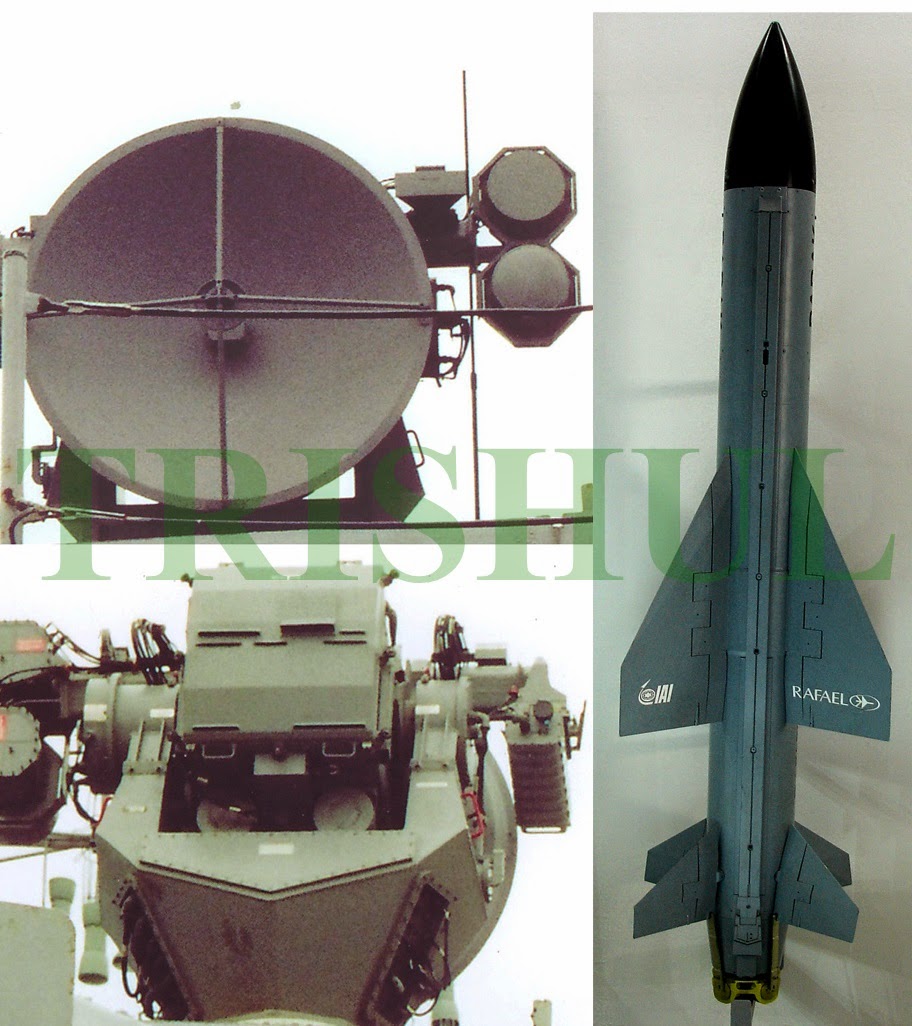

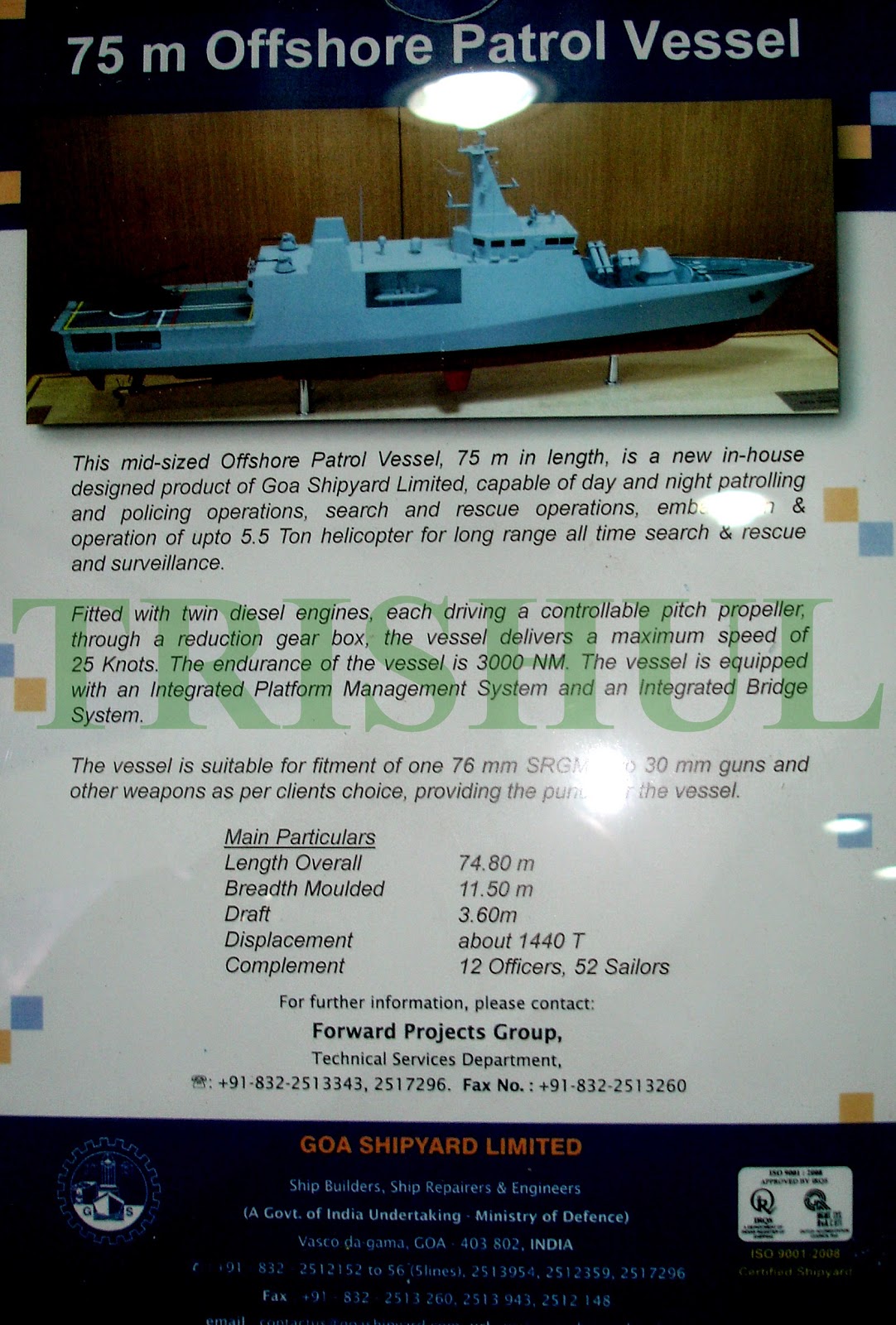

Let’s now proceed to the various approvals accorded for procurement. It was on December 23, 2013 that the DPB cleared procurement proposals worth Rs.16,000 crore (US$2.75 billion) that included 1) re-lifing of some 400 Israel Aerospace Industries-supplied Barak-1 missiles that were acquired for the Indian Navy (IN) between the years 2000 and 2005 (on October 23, 1999the 268.63 million/Rs.5.8 billion contract for procuring seven Barak-1 point-defence missile systems or or PDMS, including 224 missile rounds worth $69.13 million and 14 EL/M-2221 STGR combined fire-control radars/optronic fire directors was inked and these were subsequently installed on the aircraft carrier INS Viraat, three Project 15 DDGs and three Project 16A FFGs Brahmaputra, Beas and Betwa. By late 2003 the MoD inked a $100 million contract to acquire another four Barak-1 PDMS to be installed on three Project 17 FFGs and on INS Ran Vijay, a Project 61ME/Kashin 2-class DDG.); 2) procurement of seven new-build Barak-1 PMDS suites for the three Barch-2 Project 1135.6 FFGs and the four Project 28 ASW corvettes; 3) opening of competitive bids for supplying two deep-submergence rescue vessels (DSRV) worth Rs.1,500 crore ($258.62 million); and 4) placing orders for two Goa Shipyard Ltd-designed 75-metre naval offshore patrol vessels (NOPV), which are to be delivered to the Sri Lanka Navy as part of a financial assistance package from India to Sri Lanka. Barring the DSRV contract, all of the above-mentioned contracts have since been inked and orders placed.

![]()

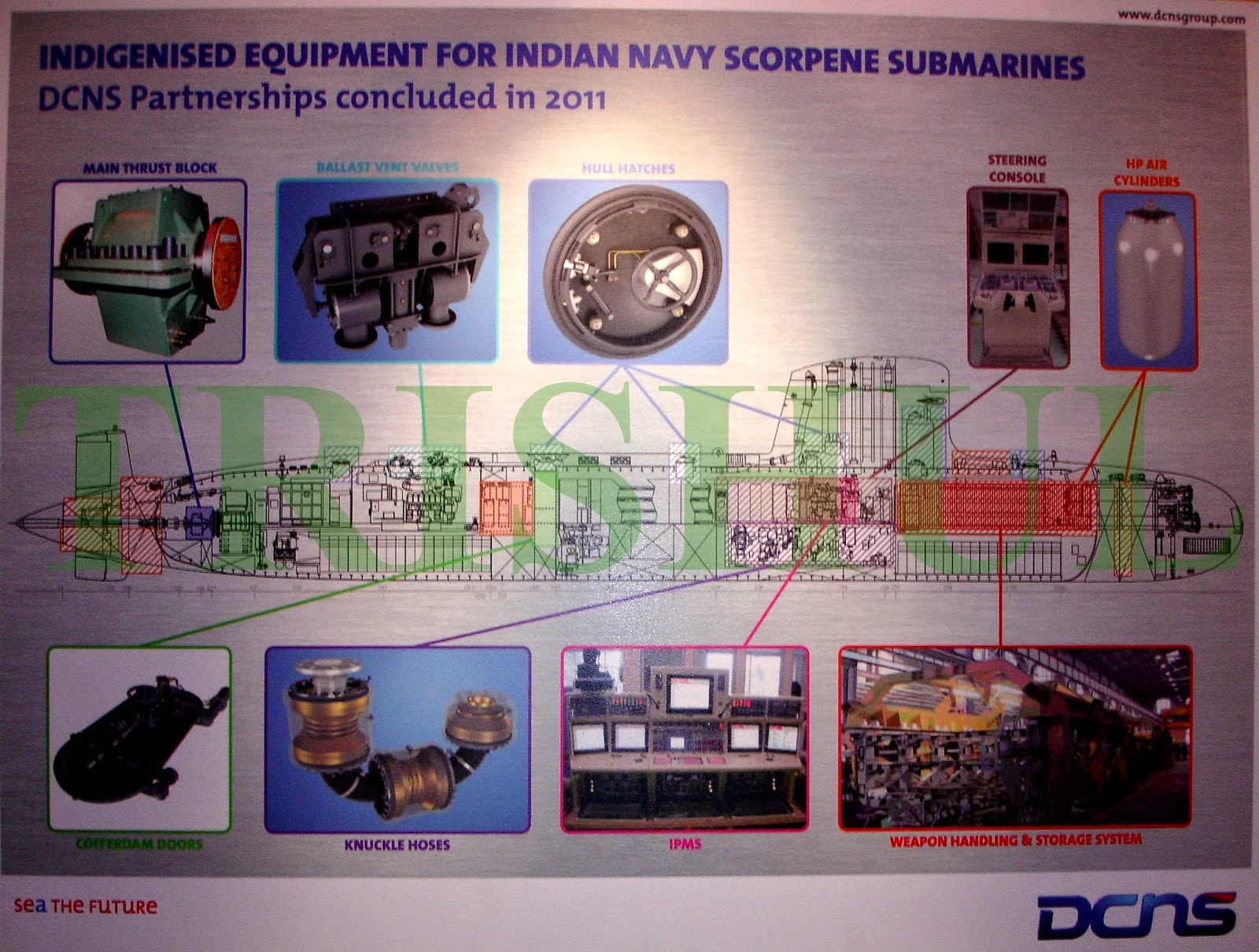

This was followed in January 2014 by the DPB’s approval for inking a contract worth $300 million Rs.1,740 crores for procuring 98 Whitehead Alenia Sistemi Subacquei-built Black Shark heavyweight torpedoes for for the IN’s six Scorpene SSKs that are due for delivery between September 2016 and late 2019. This contract, however, has yet to be inked. After orders are placed, the first 20 Black Sharks will be delivered directly by WASS, while the MoD-owned Bharat Dynamics Ltd will licence-assemble the rest from WASS-supplied completely knocked-down kits.

![]()

![]()

![]()

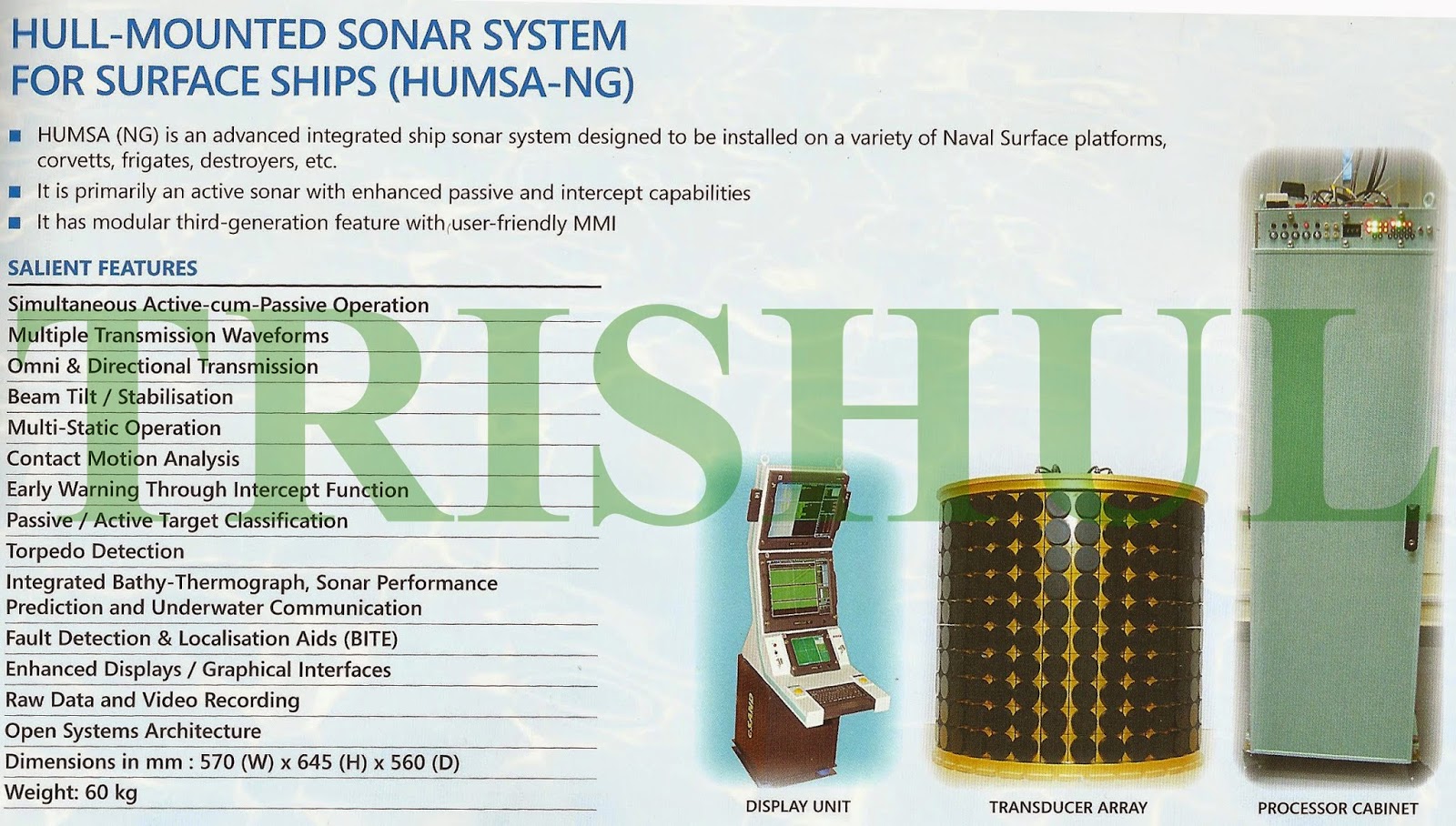

On August 30, 2014, the DPB cleared for contract signature (subject to the mandatory CCNS approval) the following: 1)Rs.4,800 crores ($827.5 million) for medium-refits of two Type 877EKM SSKs and a service life-extension programme (SLEP) for one Type 877EKM SSK, plus the mid-life upgrade of the three Project 15 DDGs; 2)Rs.1,770 crores ($305.17 million) for procuring six Atlas Elektronik-built ACTAS ultra-low-frequency towed-array sonars for the three Project 15 DDGs and three Batch-1 Project 1135.6 FFGs, procuring 10 HUMSA-NG hull-/bow-mounted panoramic sonar suites for the three Project 15 DDGs, four Project 15B DDGs and three Project 16A FFGs, and procuring traffic collision avoidance system (TCAS-2) retrofit kits for all fixed-wing turboprop aircraft of the IN; 3) Rs.6,800 crores ($1.172 billion) for procuring 118 Arjun Mk1A MBTs along with related mobile field workshops, a Base Repair Workshop, a platoon gunnery simulator, plus ammunition stocks; 4) Rs.900 crores ($155.17 million) for TAC4G broadband communications networks from Israel Aerospace Industries for the Indian Army’s Tezpur-based IV Corps, Dimapur-based III Corps and Leh-based XIV Corps; 5)22 Boeing-built AH-64D Longbow Apache attack helicopters plus related equipment and services, all collectively valued at $1.4 billion (Rs.8,120 crores), plus 15 Boeing-built CH-47F Chinook heavylift utility helicopters worth$1.4 billion (Rs.8,120 crores); and 6)16 Sikorsky S-70B Seahawk ten-tonne NMRHs worth Rs.1,800 crores ($310.34 million). Also cleared for procurement on a fast-track basis were all-terrain weapon locating radars and long-range man-portable thermal imagers for the Border Security Force (BSF), as well as close to 200 8 x 8 heavy-duty left-hand drive trucks (to be delivered by BEML-TATRA Sipox UK) for housing Pinaka-1 MBRLs their command posts, ammunition resupply vehicles and mobile field repair workshops, as well as 29 DRDO-developed/Bharat Electronics Ltd-built ‘Swathi’ weapon locating radars and their related field repair workshops. Total outstanding requirement for such trucks as of September 2010 was 1,676 units.

![]()

Lastly, funds were released for the IN’s existing Dwarka-2 forward operating base in Porbandar to be expanded into a permanent naval base that will be spread over 500 acres and will host both warships and submarines. It will be known as INS Sardar Patel.

On that very day, the DAC authorised the MoD’s DRDO to begin the process of prototype development of the Arjun Catapult. Subject to successful user-trials being concluded by early 2016, 40 such units will be ordered at a cost of Rs.820 crores ($141.37 million, or $3.53 million per unit).

![]()

As far as the present-day state of the eight surviving Type 877EKM SSKs goes, Russia’s Rubin Central Design Bureau for Marine Engineering had confirmed to me last March that the authorised total technical service life of each such SSK is not 20 years or 26 years as has been claimed by several retired IN officials over the past few days, but 35 years. Furthermore, each such SSK undergoes only one medium refit (inclusive of a mid-life upgrade) once after completing 13 years of service, and on its 26th year in service, it will undergo a service life-extension programme (SLEP) or a long-refit (inclusive of further upgrades) so that it will remain in service for a total period of 35 years. As part of the SLEP for the remaining eight Type 877EKM SSKs, the IN in future plans to equip them with thin-line towed-array sonars as well as new-generation optronic periscopes. Thus, while the IN will by 2018 be able to muster eight Project 08773 SSKs and retain the last of them in service will 2027.

![]()

The Severodvnsk-based Zvezdochka State Machine-Building Enterprise has to date upgraded five of the eight Type 877EKM SSKs to Project 08773 standard at an aggregate cost of Rs1,560 crore (or an average of US$156 million per unit):

* INS Sindhughosh S-55, whose keel was laid on May 29, 1983, was launched on July 29, 1985 and was commissioned on November 25, 1985 and it was subjected to a medium-refit and was also upgraded to Project 08773 standard between 2002 and 2005.

* INS Sindhudhvaj S-56, whose keel was laid on April 1, 1986, was launched on July 27, 1986 and was commissioned on November 25, 1986.

* INS Sindhuraj S-57, which was commissioned on September 2, 1987, was subjected to a medium-refit and was also upgraded to Project 08773 standard between 1999 and 2001.

* INS Sindhuvir S-58, which was commissioned on December 25, 1987, was subjected to a medium-refit and was also upgraded to Project 08773 standard between 1997 and 1999.

* INS Sindhuratna S-59, which was commissioned on August 14, 1988, was subjected to a medium-refit and was also upgraded to Project 08773 standard between 2001 and 2003.

* INS Sindhukesari S-60, which was commissioned on October 29, 1988, was subjected to a medium-refit and was also upgraded to Project 08773 standard between 1999 and 2001.

* INS Sindhukirti S-61, which was commissioned on October 30, 1989, has been declared as a writeoff.

* INS Sindhuvijay S-62, which was commissioned on October 27, 1990, was subjected to a medium-refit and was also upgraded to Project 08773 standard between 2005 and 2007.

* INS Sindhurakshak S-63, which was commissioned on October 2, 1997, was subjected to a medium-refit and was also upgraded to Project 08773 standard between August 2010 and January 2013.

Next in line for a medium-refit and upgrading to Project 08773 standard is INS Sindhushastra S-64, which was commissioned on May 16, 2000. This will be followed by the medium-refit of INS Sindhudhvaj S-56.--all this being confirmed by the MoD way back in September 2013. Contracts for both medium-refits will be concluded between 2015 and 2019. INS Sindukesari S-60 will soon proceed to Severodvnsk for its final SLEP.

Project 75 Conundrum

ARMARIS’ then Chairman Peter Legros had on July 10, 2005 confirmed that a revised package was being finalised under which an adjustable price mechanism (known as REM) to offset the cost escalations caused by delays in finalisation of the Project 75 contract (involving the licenced-construction of six single-hulled 1,565-tonne CM-2000 Scorpene diesel-electric submarines—all to be assembled by the MoD-owned Mazagon Docks Ltd, or MDL) would be arrived at by the MoD’s Price Negotiations Committee in the near future. On October 6, 2005 the contract for was finally inked, with the then French Ambassador in New Delhi Dominique Girard and the MoD’s Additional Secretary (Acquisitions) D Banerjee signing on the contract worth Rs 18,798 crore. Of this amount, Rs.2,700 crores (400 million Euros) was set aside for MDL to place orders with both foreign OEMs and local vendors for materials (all grouped under the category MDL-Procured Materials, or MPM) like 80 HLES high-yield steel steel (coming from ArcelorMittal), pipings, shaftings and valves. The contract also stated that the MoD had the option of procuring another four MDL-built Scorpene SSKs between 2015 and 2020—these being the AM-2000 version of the Scorpene and equipped with an AIP plug-in module. Metal-cutting for the first CM-2000 SSK began on May 25, 2007, and keel-laying of the first three SSKs took place in December 2006, December 2007 and August 2008, respectively. By late 2009, however, it had become evident that the various India-based industrial vendors that had been contracted for supplying the pipings, shaftings and valves had failed to comply with the stringent build-specifications of both DCNS of France and Spain’s Navantia (which together had formed the ARMARIS consortium). In fact, both the IN and MDL had warned the MoD about such an eventuality and had suggested way back in mid-2005 that of the six CM-2000 SSKs, the first two ought to be built at DCNS’ Cherbourg-based shipyard (if this was done, then the IN would have received its first two CM-2000s by late 2012) and during their manufacturing stages, the various contracted Indian industrial vendors would be mentored by their French and Spanish counterparts to attain the required degree of production competencies, thereby ensuring consistency in QC and QA levels once MDL began licence-building the remaining four Scorpene SSKs. However, since this did not happen, as predicted, the Indian vendors failed to produce components that were compliant with OEM-mandated specifications and this, consequently forced MDL to exercise the only option then left on the table: place orders with France-based and Spain-based OEMs for supplying such components at an extra cost of Rs.4,700 crores (700 million Euros). Consequently, the total cost of Project 75 was hiked to Rs.23,562 crores in February 2010, along with revisions in delivery schedules. New indents for MPMs were placed between mid-2010 and November 2012. On top of all this, internal project mismanagement by MDL created additional complications. For instance, although four batches of a total of six CD-based Transfer of Design Data (TDD) packages had reached MDL by the first quarter of 2013, they could not even be opened because the CAD-5 software to run the CDs had not been acquired by MDL. Similarly, though DCNS had advised MDL in 2006 to buy a 2000-tonne press for bending the thick steel plates supplied byArcelorMittal, MDL acquired it only in 2011. By then, the contract for bending the steel plates had been outsourced to Pipavav Defence & Offshore Engineering Ltd. The press now lies idle in MDL, with no steel to press since all the hulls have already been made. MDL had also signed a 65 million Euros contract with both DCNS and Navantia for deputing an ‘Advising & Overseeing Team’, and ended on March 15, 2013 and this contract was renewed only late last year. The first Scorpene SSK is now scheduled for delivery in September 2016 (instead of December 2012 as originally planned), and thereafter, one each every nine months through to May 2019.

![]()

The above shameful saga only raises some pertinent questions that no one has bothered to ask so far: why did the MoD and its Department of Defence Production & Supplies, along woth the Govt of India’s Department of Industrial Policy and Promotion (DIPP) decide to licence-build all six Scorpene CM-2000 SSKs despite the grave reservations expressed by both IN HQ and MDL? And did anyone or a group of officials making up the decision-making loop become direct or indirect financial beneficiaries through such willful criminal negligence at the cost of the Indian exchequer?

![]()

This then brings us to the option for procuring the four AM-2000 SSKs. While the performance parameters of both the CM-2000 and AM-2000 variants remain the same, the length of the AM-2000 increases to 70 metres and its submerged displacement is 1,870 tonnes, against the 61.7 metres and 1,565 tonnes of the CM2000. Both SSK variants will have a crew complement of 31 (with a standard watch-team of nine) and endurance of 50 days. The AM-2000’s hull too will be built with HLES-80 high-yield stress-specific steel, which will allow the SSK to reach diving depths of up to 300 metres (1,150 feet) and achieve an average of 240 days at sea, per year, per submarine. The AM-2000, just like the IN’s six CM-2000s, will also feature a connection point for allowing a DSRV to dock during collective crew-rescue operations.

Though the DRDO’s Ambarnath-based Naval Materials Research Laboratory (NMRL), along with the Kochi-based Naval Physical and Oceanographic Laboratory (NPOL), have since 2002 been trying to developing an on-shore fuel cell-based air-independent propulsion (AIP) system that will enable an SSK to stay submerged continuously for about 25 days, till to date, no significant R & D breakthroughs have been achieved nor are they expected to be achieved in the latter half of the decade. Apart from the NMRL and NPOL, other DRDO laboratories and industrial entities that are involved with this R & D venture are Larsen & Toubro, THERMAX, IOCL, TEXOL, Indian Institute of Petroleum, AKSA, CEEFES, C-DAC, DIGITRONICS, NSTL, RCI, ROLTA and MDL. This then leaves the IN with only two AIP options: either go for the DCNS-developed MESMA (Module d’Energie Sous-Marine Autonome) system, or opt for the Stirling Engine. In MESMA, ethanol and liquid oxygen are mixed in a high-pressure burner to a temperature of 700 degrees Celsius, which acts as a heat source for a primary water-loop, which is pressurised at 60 bar, thereby allowing operations to full diving depth (a bar is a measure of pressure roughly equivalent to one atmosphere; at the sea surface the pressure is 1 bar, at 10 metres it is 2 bar, at 20 metres it is 3 bar, at 100 metres it is about 10 bar and at 600 metres it is 60 bar). The primary loop passes through a steam generator. The steam, which is greater than 20 bar and 500 degrees Celsius, spins a turbine attached to an alternator. The alternator charges the SSK’s battery. The MESMA AIP on the three Agosta 90B SSKs of the Pakistan Navy is capable of producing 200kW of energy, which provides enough energy to for a light battery-charging rate when the SSK is cruising at 6 Knots. Newer versions of MESMA use diesel instead of ethanol that, like the Stirling Engine, limits the additional AIP fuel supply to just liquid oxygen.

The Stirling-based AIP is a closed-cycle engine that uses helium as the working fluid. Diesel and liquid oxygen are mixed in a high-temperature burner to a temperature of 750 degrees Celsius, which acts as a heat source for an enclosed quantity of helium. The helium is driven through a repeating sequence of thermodynamic changes. By expanding the helium against a piston and then drawing it into a separate cooling chamber for subsequent compression, the heat from the external combustion of diesel and oxygen can be converted into work that can then be turned into electrical energy by a DC generator. The DC generator charges the battery. Gases from the process are mixed with cooling water in a special carbon dioxide dissolver and discharged into the sea. This AIP uses less pressure than a MESMA, operating at 20 bar. Each Stirling Engine is capable of producing 75kW of energy, with two or more installed on each SSK.

Blowing The Lid Off The INS Sindhukirti Saga

For far too long, the ‘desi’ band of journalists covering national security issues has consistently alleged that almost all foreign OEMs—and especially those hailing from Russia—have never lost any opportunity to take India for a ride, that India has always been at the receiving end of their ‘devious’ marketing efforts, and consequently, India can never depend upon such OEMs when it comes to the crunch. The most recent example of ‘yellow journalism’ has appeared here:

News-reports like the one highlighted above always inevitably contain only selective facts, which in turn tell only one side of the story, and consequently, the truth always becomes the first casualty. So what exactly is the hitherto-untold saga of the INS Sindhukirti? To get to the bottom of matters, we need to go back to the year 2004 when the IN has headed by Admiral Madhvendra Singh(he was the Chief of the Naval Staff between December 29, 2001 and July 31, 2004). INS Sindhukirti had by then been in service for 15 years and was due for its mid-life medium-refit—a job that could be done only at a Russian shipyard—since neither the USSR nor Russia had ever allowed/authorised any other shipyard abroad (be in it India or China) to undertake such jobs.

![]()

It was at this time that Chennai-based The India Cements Ltd’s N Srinivasan (presently its Vice Chairman & Managing Director and also Chairman of the ICC) teamed up with a former IN submariner by the name of Commodore S Shekhar (see his bio-data at: http://www.globalsar.com.my/shekhar.html), who is the Promoter and Managing Director of JMPS Sanjivini Consultants (Pvt) Ltd, for exploring ways and means of entering India’s market for submarine MRO-related businesses. Together, Srinivasan and Shekhar did a detailed feasibility study on the prospects of conducting in-country medium-refits of the IN’s fleet of Type 877EKM SSKs in cooperation with Russia-based OEMs. The feasibility study, conducted with the assistance of Russia’s Rosoboronexport State Corp, was next taken to the Chairman & Managing Director (CMD) of state-owned and Vizag-based Hindustan Shipyard Ltd (HSL), Rear Admiral (Ret’d) Ajit Tewari, who was previously the Assistant Chief of Naval Staff (P & P) at Naval HQ and after his retirement, became HSL’s CMD on February, 3, 2004. This where the scene gets murky, since Naval HQ sometime in mid-2004 authorised HSL (which came under the MoD’s administrative control only on February 8, 2008) to begin work on INS Sindhukirti’s medium-refit (with Srinivasan and Shekhar reportedly acting as project consultants for HSL) despite the fact that HSL had by then not inked any kind of military-industrial agreement with Rosoboronexport State Corp (consequently, HSL at that time was not authorised by either the Govt of the Russian Federation or any Russian OEM for undertaking any kind of medium-refit-related activity on any Type 877EKM SSK). ![]()

It was only on October 3, 2006 that Rosoboronexport State Corp inked a Rs.650 crores contract with HSL for rendering industrial-cum-technological assistance to HSL for undertaking the INS Sindhukirti’s medium-refit-cum-upgrade—a task that was originally due for completion by 2010. Rosoboronexport State Corp in turn signed a back-to-back contract with the Severodvnsk-based Zvezdochka State Machine-Building Enterprise, which became HSL’s principal industrial partner for executing the INS Sindhukirti’s medium-refit-cum-upgrade. Zvezdochka subsequently began materials supplies as well as turn-key activities that included: completion of entire degutting in May 2007, completion of blasting on the entire hull structure for defect survey in February 2008, removal of hard-patches from all six compartments, installation and commissioning of two pipe-bending machines at HSL, and qualifying and type-certifying HSL’s welders to take up repairs on INS Sindhukirti’s hull structures. And by May 2008, Zvezdochka had delivered to HSL all technical/engineering documentation that was required for undertaking the medium-refit-cum-upgrade.

![]()

The question that then arises is, why will INS Sindhukirti be delivered to the IN only in March 2015, when Zvezdochka takes between 24 and 28 months to refit-cum-upgrade a Type 877EKM SSK? The answer is elementary: it is all about skilled human resource mobilisation. Zvezdochka typically employs more than 200 personnel in three shifts to complete the job in two years, while HSL until late 2008 could mobilise only 50 workers. Furthermore, HSL bagged the contract for INS Sindhukirti’s medium- refit-cum-upgrade at a time when highly skilled human resources like welders were in high demand at the nearby Ship Building Centre (SBC), which had then been leased by the MoD to Larsen & Toubro (L & T) for undertaking final assembly of the S-2/Arihant SSBN’s hull superstructure. L & T, which began shipping the S-2/Arihant’s hull-rings (fabricated at Hazira) and internal bulkheads and fitments (fabricated at Powai), literally poached all of HSL’s pool of skilled human resources by offering them much higher salaries and related perks—all of which left HSL high-and-dry. HSL consequently had no other option but to recruit new personnel and with Zvezdochka’s assistance, train them from scratch until they could acquire a credible degree of job proficiency—a task that easily consumed almost four years. And that’s the reason why INS Sindhukirti’s medium-refit-cum-upgrade could not be completed by 2010 as originally scheduled.

(to be concluded)

%2B%26%2BELM-2248%2BMF-STAR.jpg)

%2B%26%2B1954.jpg)

%2B%26%2BTD-500ER%2B500kg%2BGPS-guided%2Bglide%2Bbomb.jpg)

%2B%26%2BRajendra%2BPESA%2Bengagement%2Bradar-1.jpg)