Myanmar’s Tatmadaw (armed forces) in early November 2013 inked a contract with CPMIEC of China under which the latter will, starting June 2014, begin delivering a regiment of KS-1A medium-range surface-to-air missile (MR-SAM) system. This is China’s first export order for the KS-1A MR-SAM, which has been on offer for export worldwide since the late 1990s. Bangladesh’s air force, meanwhile, is close to ordering from South Korea the Cheongung (Iron Hawk) MR-SAM, co-developed by a consortium of entities that included Russia’s Almaz Design Bureau, the ADD, LIG Nex1, Samsung-THALES and Doosan DST, was developed within a five-year period and entered the series-production phase last year. In Russia, the Cheongung will soon be produced as the S-350E Vityaz.

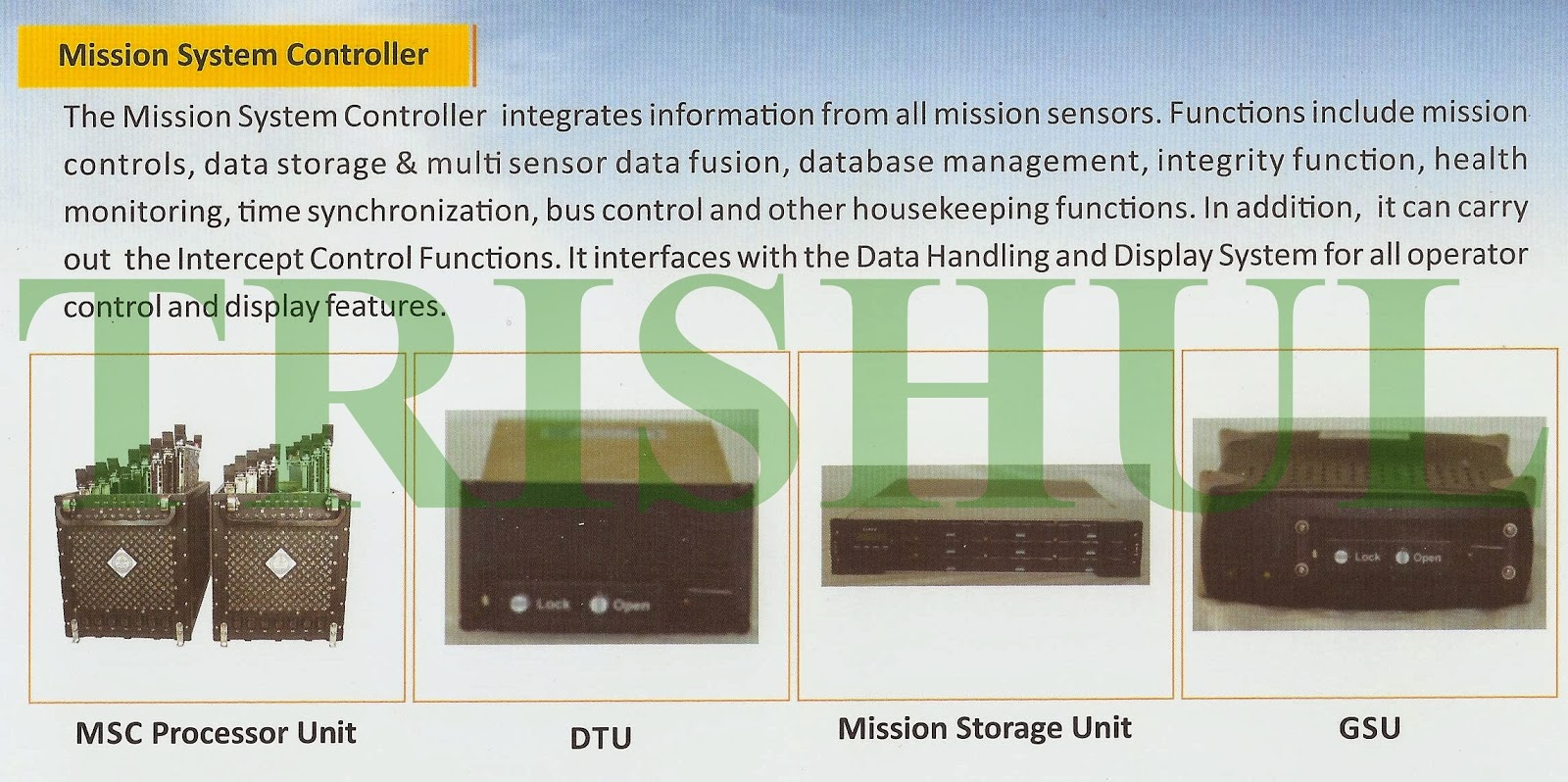

![]()

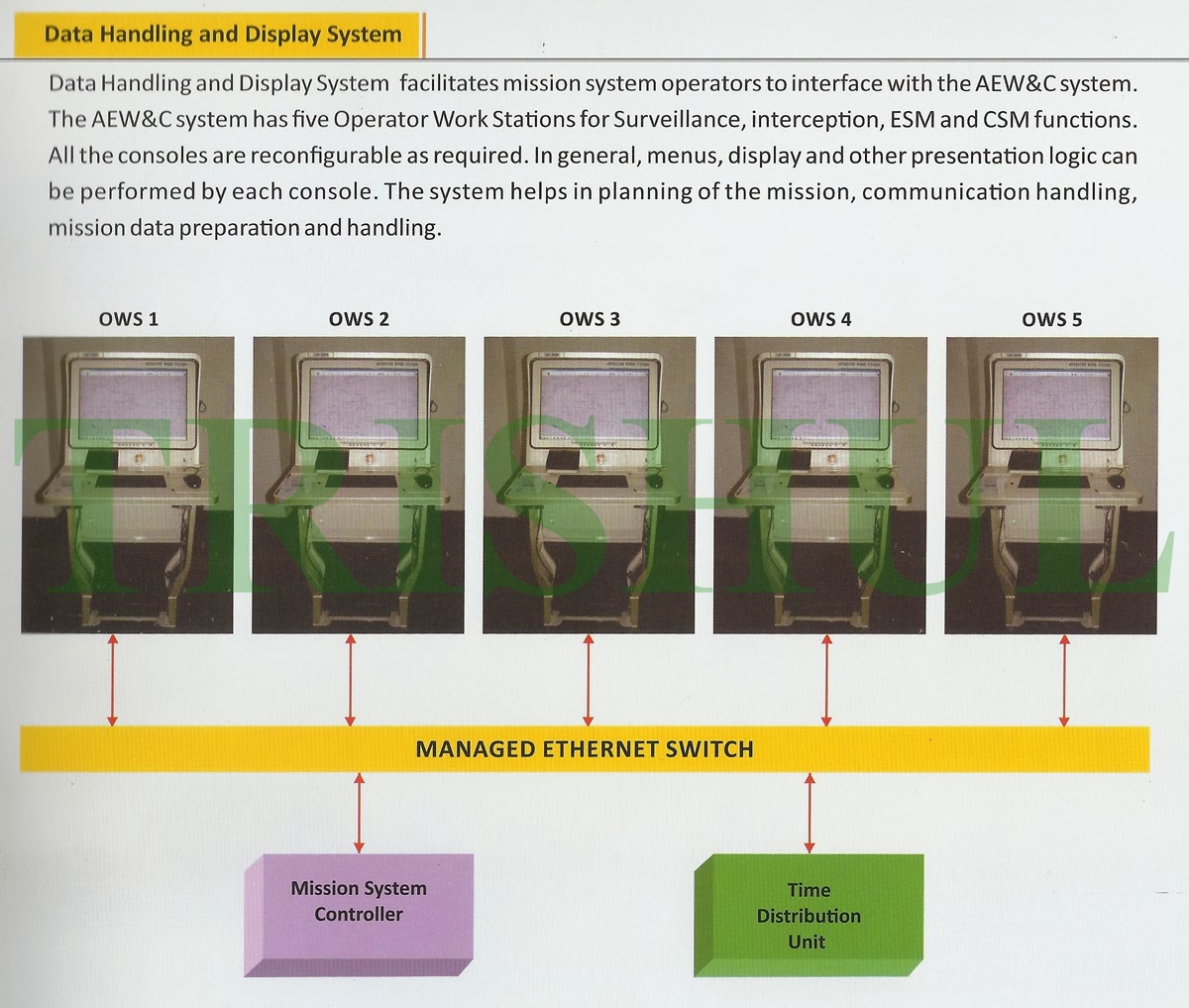

![]()

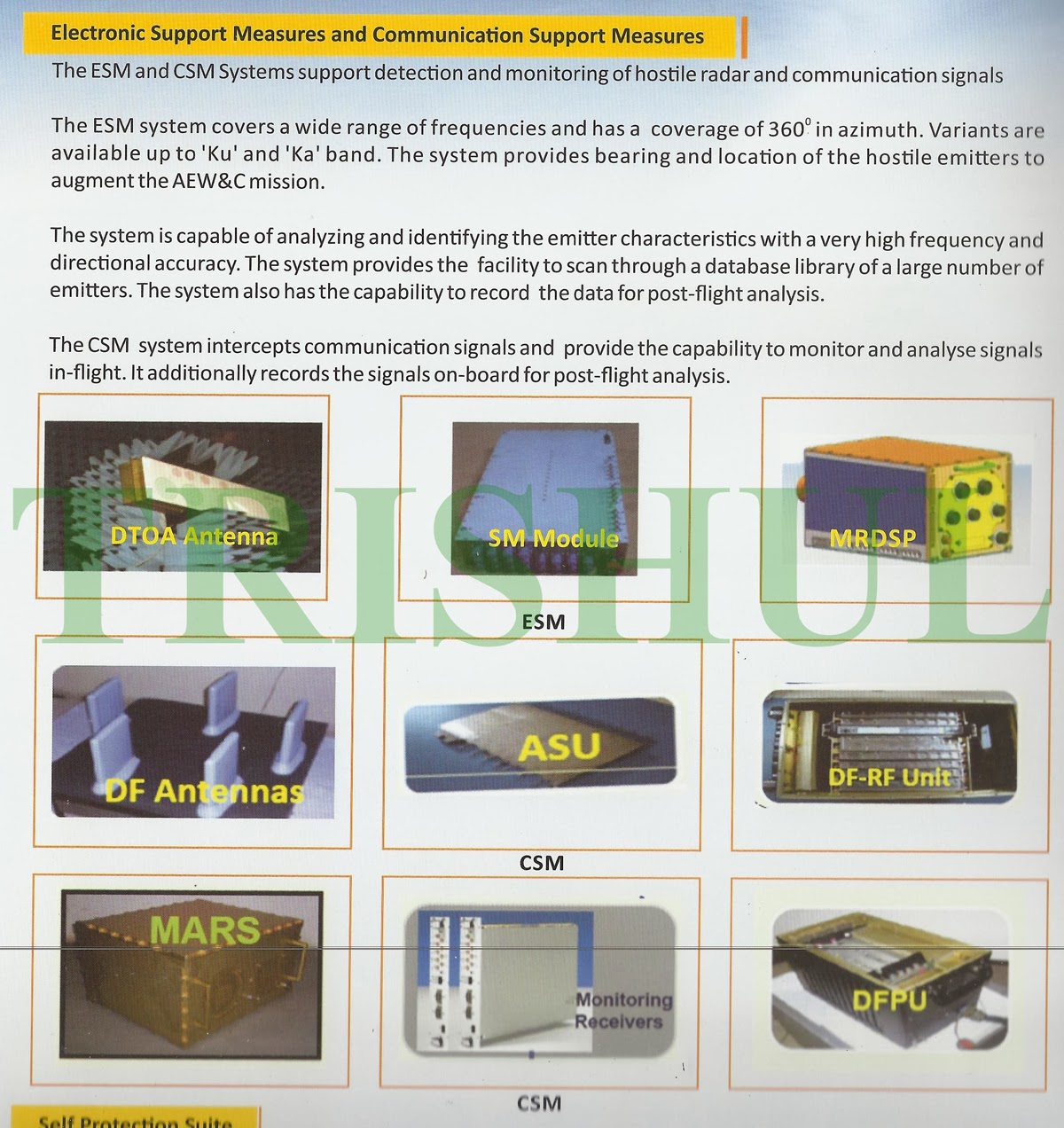

The KS-1A can serve as a close-in area air defence system to complement the more advanced systems, as well as performing as a gapfiller to preclude the need for additional, expensive strategic SAM systems. It was developed in the 1980s as a replacement for the HQ-61 SAM system. Due to reasons which have not been publicly disclosed, the KS-1 did not enter military service in China when development was completed in 1994. A likely reason was the poor manoeuvring capability of the missile. It could only engage targets with a 5g manoeuvring capability, making the KS-1 largely ineffective for defending against new-generation combat aircraft. The KS-1A is presently operational with both the PLA Army and PLAAF as the HQ-12 MR-SAM. The latest version of the system is known as the KS-1C, which features cannister-encased missile rounds.

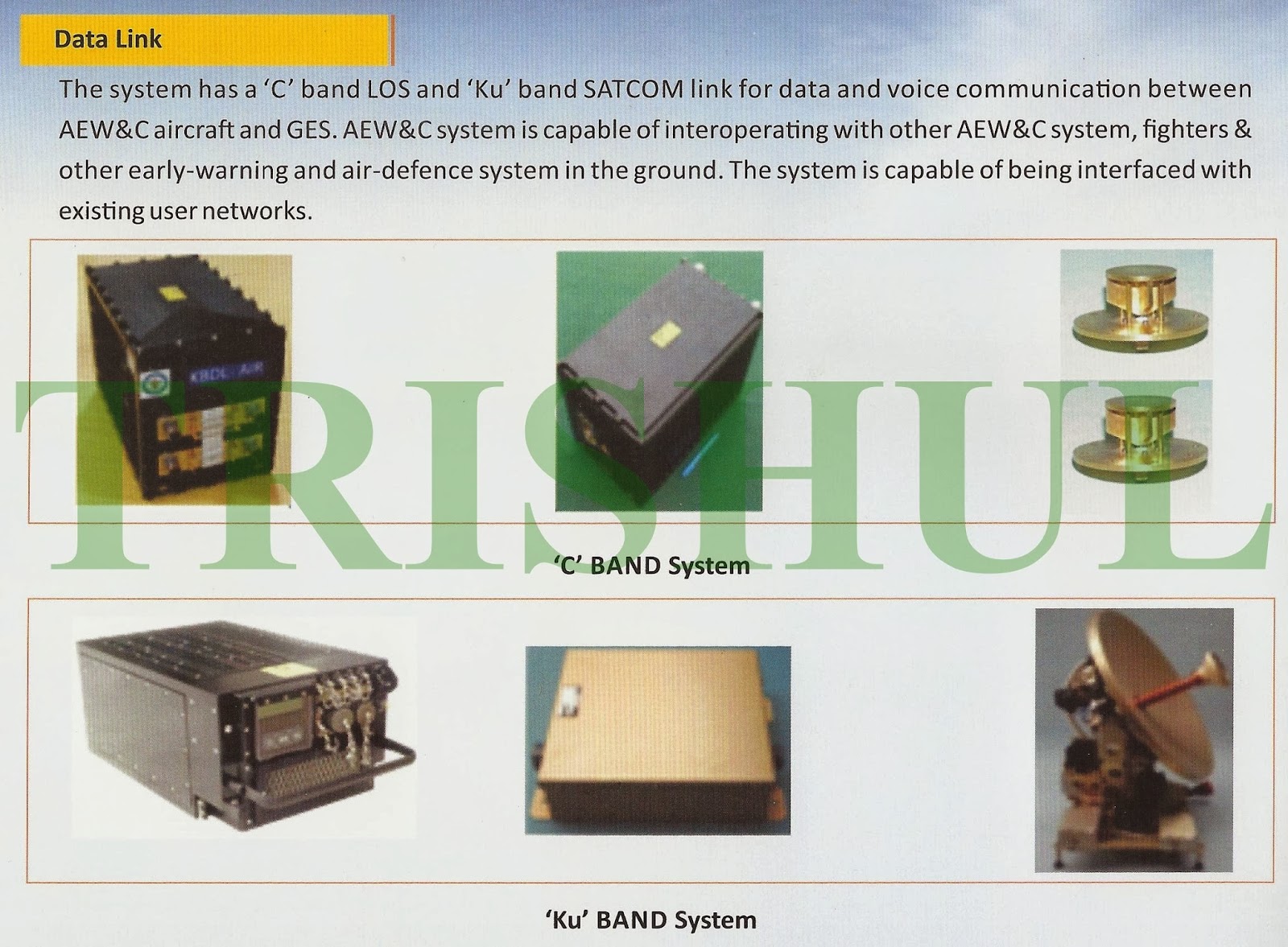

![]()

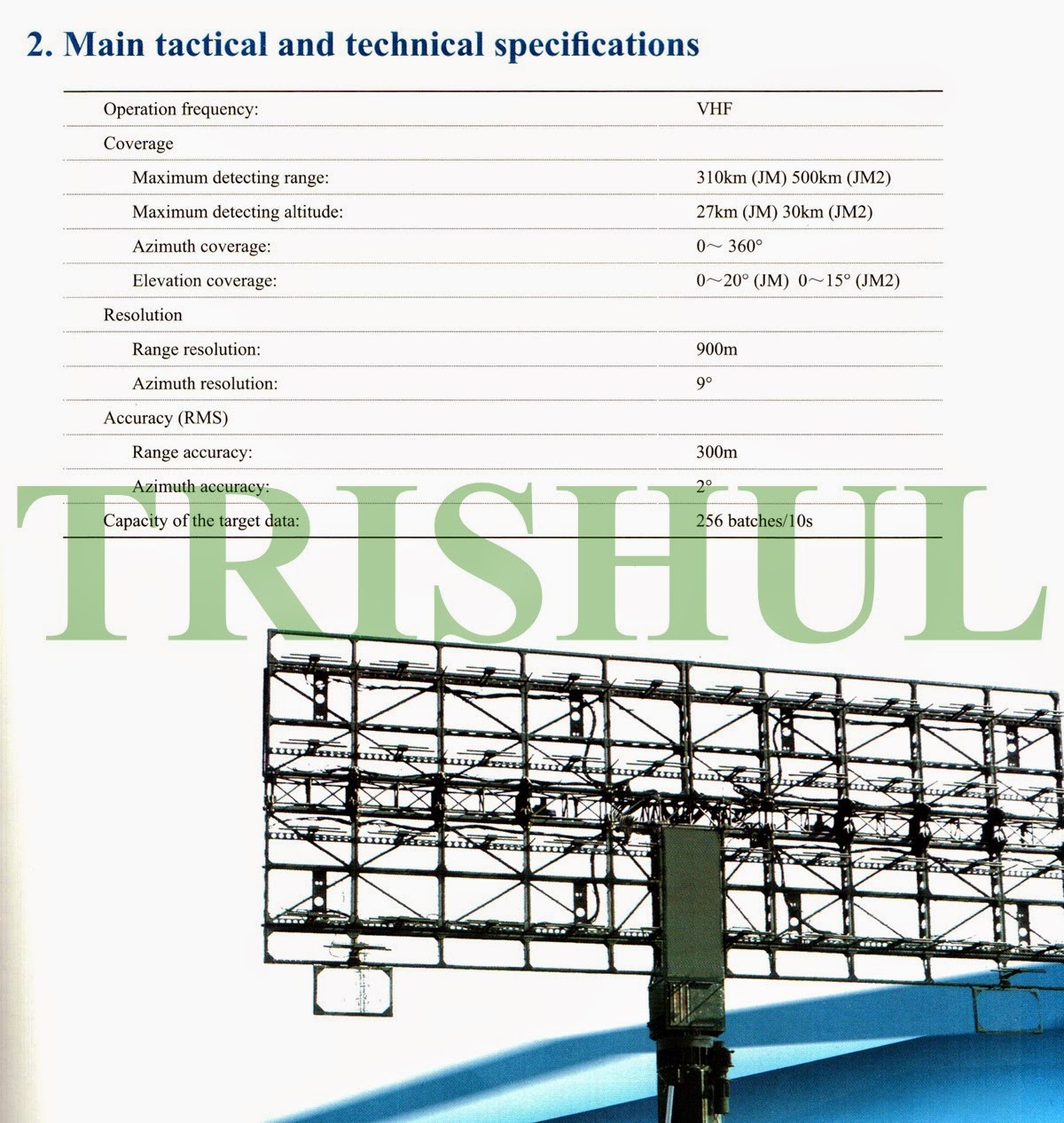

The PRC’s 2nd Aerospace Academy, now known as China Academy of Defence Technology, or CADT, (also known as the China Changfeng Mechanics & Electronics Technology Academy) of the 7thMinistry of Machinery Industry (now known as CASIC), in 1981 began developing a 57.5km-range tactical endo-atmospheric interceptor missile called the KS-1, which was meant to intercept incoming tactical ballistic missiles. The first test-firing of the missile took place in 1989 and the KS-1 system was first publicly revealed at Le Bourget during the 1991 Paris Air Show. All R & D work on the KS-1 was concluded in 1994, following which series-production of the MR-SAM rounds began at the Gui Yang-based Guizhou Aerospace Industry Company Ltd. The newer KS-1A’s TWS-312 engagement control centre (ECC) and its SJ-231 missile guidance system (that includes the C-band HT-233 passive phased-array tracking-cum-engagement radar) are series-produced by the Xi’an-based Shaanxi Tianhe Industry Group. The latter two are mounted on TAS-5380 8 x 8 heavy-duty cross-country vehicles.

![]()

The KS-1A employs a single-chamber dual thrust, solid-fuelled missile, weighing 886kg, and comes equipped with a command line-of-sight guidance system under which mid-course correction commands are transmitted to the guidance system from the ECC. A control actuator system is located at the tail end of the missile behind the propulsion system. The HT-233 radar carries out airspace search, target detection, target track, identification, missile tracking, missile guidance and electronic counter-countermeasures (ECCM) functions. The HT-233 radar is automatically controlled by a digital weapons control computer housed within the ECC, and cable link is used to connect the SJ-231 to the TWS-312, which is the only manned station in a KS-1A Battery and it provides the human interface for control of all automated functions. The ECC communicates with all KS-1A Fire Units as well as with higher-echelon command headquarters, and has on board an Air Situation Display console and Tracking Display console that adopt customised BITE technologies, and have embedded simulated training software for engaging more than 100 airborne targets in various flight profiles, all of which can be used for operational training in peacetime.

![]()

![]()

The HT-233 radar, operating in the 300MHz bandwidth, has a detection range of 120km and tracking range of 90km. The radar antenna has 4,000 ferrite phase shifters. It can detect targets in azimuth (360°) and elevation (0° to 65°). It can track some 100 airborne targets and can simultaneously engage more than 50 targets when used in conjunction with a Brigade-level ECC (which can handle automatic command-and-control of three subordinate HQ-12/KS-1A Regiments). In some cases a KS-1A Fire Unit receives early warning of enemy ballistic missile launch, along with direction and time-of-arrival data. Target engagement can be carried out by the HT-233 in manual, semi-automatic or automatic mode. When the decision has been made to engage the target, the ECC selects the Launch Battery or Batteries to be used and pre-launch data is transmitted to the selected missile via microwave line-of-sight data links. The target position data is downloaded to the missile to aid the missile’s target acquisition. After launch, the missile is acquired by the HT-233 radar.

![]()

The missile’s track command up-link and down-link between the missile and the HT-233 allows the missile’s flight to be monitored and provides missile guidance commands from the ECC’s weapons control computer. As the missile’s closest approach to the missile is reached (50 metres), a proximity fuze detonates the directional high-explosive blast fragmentation warhead. The missile’s engagement zone is between 300 metres and 27km in terms of altitude, while it has a slant range of between 7km and 57km, and a maximum speed of 1,200 metres/second. The KS-1A Fire Unit includes a 6 x 6 TAS-270A vehicle housing a slewable oblique under-rail suspension dual launcher carrying two missile rounds. The Fire Unit can deploy in three ways: the vehicle mode, the trailer mode, and the stand-alone mode. It carries two ready-to-fire missiles, is capable of remote operations, and is 360-degree slewable.

![]()

To make the KS-1A a cost-effective yet lethal MR-SAM, it was decided to adopt the command-link guidance approach. Under this, the HT-233 radar (using an integral IFF transponder, a spectrally pure TWT transmitter, two-stage superheterodyne correlation receiver for channels, high-speed digital signals processor, real-time engagement management computer, secure guidance command up-link, and a radar data processor) would accurately track both the airborne target and launched missile, while a flight/trajectory control computer inside the SJ-231 would calculate the required flight-path corrections for the missile, which would then be transmitted via a data-link to the missile’s on-board digital flight control system (including a digital autopilot, telemetry command receiver and decoder, and a transponder) for bringing the missile as close as 50 metres to the targetted aircraft, following which the proximity fuze will trigger the HE fragmentation warhead.

![]()

Presently, one KS-1A Battery can simultaneously engage three targets with missiles, and comprises 36 missiles, one SJ-231 ECC station and one HT-233 radar (for 3-D target search, detection, acquisition, identification and engagement; clutter rejection and missile guidance), one Type 305A S-band 3-D mobile tactical air defence radar (with a 250km-range), three power supply vehicles, six 6 x 6 missile launcher vehicles (that are dispersed to launch sites located up to 10km away from each other, with the launch platforms being microprocessor-driven and controlled through an electro-mechanical servo system), six missile transporter-loading vehicles, one tractor, one missile-test vehicle, three missile transport vehicles, one electronics maintenance vehicle, two tools vehicles, and one power supply vehicle.

![]()

When networked with a Brigade-level ECC, a kill probability of not less than 90% of small-formation airborne targets (less than four aircraft whose airspeed is not greater than 700metres/second) can be achieved (when ripple-firing two missiles against a single target), and more than 95% when the target’s speed is not greater than 560 metres/second and the intruding airborne target density is not greater than four aircraft a minute. In terms of performance, therefore, the KS-1A is in the same league as (but much cheaper than) Raytheon’s RIM-162 Evolved Sea Sparrow Missile (ESSM), while being superior to the 45km-range BUK-M2E of Russia’s Almaz Antey Concern.

![]()

The improved KS-1A was publicly revealed at the Zhuhai Air Show in 2000. It is a command-guided missile with a range of 57.5km, capable of intercepting targets at altitudes of up to 27,000 metres. It enjoys a 15km increase in effective range over the earlier HQ-61, and as such represents a relatively significant improvement in air defence capability. The KS-1C variant made its public debut at the 2012 Zhuhai Air Show.

![]()

![]()

The KS-1A MR-SAM is extremely flexible in employment and deployment. It is best employed as a Regiment. However, its three Batteries can be employed for independent tasks if required. This is called the Autonomous Mode. The three Batteries can be deployed in various geometric formations, as suited to the vulnerable area/point being protected and the extent desired to be sanitised from hostile airborne threats. Similarly, the Battery can deploy its launchers in a way as to be optimal for target engagement as the threat is perceived ab-initio, or as it evolves during combat. Cross-country mobility enables quick re-deployment and the radar-based sensors can be so positioned as to achieve the optimum kill zone. The KS-1A Batteries can protect static, semi-mobile as well as mobile assets. These may be critical national assets in the hinterland or large mobile armoured formations (either Integrated Brigade Combat teams or Armoured Divisions) thrusting into enemy territory. The Regimental ECC and the Battery-level ECCs must be deployed in a manner, which will provide a clear line-of-sight to the Batteries, which may be placed up to a maximum of 30km away from each other. This requires the mast of the microwave communications antenna (on the radars, ECCs and Firing Units) to be raised to the required appropriate height.

![]()

The Type 305A radar must be sited while keeping in mind the screening constraints. The radar’s antenna must be aligned accurately by knowing its position and orientation with respect to the north. This information is made available to the Type 305A’s mission computer from a fibre-optic gyro-based autonomous land navigation system (ALNS). Care should be taken to align the Type 305A’s antenna with the ALNS and the system must be calibrated. The levelling of the Type 305A’s antenna needs to be accurate in order to avoid any tilt, which would introduce a bias. The SJ-231 is also provided with ALNS to measure its latitude, longitude and orientation with respect to the true north. This information is required by both Battery-level ECC and the Type 305A’s mission computer. The MR-SAM Firing Units operate automatically and are remotely controlled by the Battery-level ECC, which may be up to 1.5km away. Control is effected via microwave line-of-sight radio or line-cable links.

![]()

The Type 305A automatically starts tracking targets at a distance of around 250km providing early warning to the KS-1A system and its operators. The target track information is transferred to Regimental ECC, which automatically classifies the targets. The three HT-233s start tracking targets around a range of 100km. This data too is transferred to Regimental ECC, which then performs multi-radar tracking and carries out track correlation and data fusion. Target position information is then sent back to the HT-233s, which use this information to acquire the prioritised targets with the help of the Battery-level ECC, which can engage a target(s) from the selected list at the earliest point of time, and is is assigned the target in real-time by the Regimental ECC. The availability of missiles and the health of the missiles are also taken into consideration during this process. Fresh targets are assigned as and when intercepts with assigned targets are completed. A single shot kill probability (SSKP) of 98% has already been achieved by the system taking into consideration various parameters of the sensors, guidance command, missile capabilities and kill zone computations.

![]()

There are a number of possibilities for deploying the KS-1A in autonomous Battery-level mode and in Regimental-level mode for neutralising the threat profiles with optimally defined multi-target engagement scenarios. In the Regimental-level mode there are a number of proven configurations to defend vulnerable areas depending upon the nature of the expected threat pattern and characteristics of the threats. Similarly, up to four B batteries in autonomous mode can be deployed to defend vulnerable areas/points. In all its deployment patterns, the KS-1A offers a multi-target and multi-directional area air defence capability. All its ground-based and airborne components are integrated in a plug-and-flight architecture under which the software-based integration of all hardware-based elements permits the autonomous management of various functions such as programmable surveillance, target detection, target acquisition, target identification and tracking, threat evaluation, threat prioritisation, interception assignment and target engagement.

![]()

Depending on the operational scenario—whether to defend a vulnerable area or vulnerable point—the KS-1A’s operational deployment pattern can be selected from either of the three above-mentioned types. In all the three patterns, up to four KS-1A Batteries (with 48 ready-to-fire missiles and four SJ-231 stations) can function together seamlessly even when deployed over a wide area and are linked to a Regiment-level ECC by secure microwave line-of-sight data links as well as mobile troposcatter communications terminals. When an entire Regiment of KS-1A MR-SAMs is deployed, use is made of a Type 305A ‘gapfiller’ airspace surveillance radar to provide a single integrated airspace picture to the Regimental ECC. The Type 305A and four SJ-231 stations can be networked with a Sector Operations Centre (SOC) via a DA-6 tactical internet controller using either underground fibre-optic links or land-mobile broadband, multi-channel, beyond line-of-sight, digital troposcatter communications terminals.

![]()

This same type of systems architecture using the above-mentioned tools can be employed to develop an integrated, hierarchical air defence network that seamlessly integrates the LR-SAM, MR-SAM, E-SHORADS and VSHORADS into one monolithic guided-missile-based air defence system. To make the HT-233 radar virtually invulnerable to hostile electronic jamming, a number of ECCM features have been incorporated, including narrow transmit and receive beams, very low sidelobe antenna, automatic frequency selection mode, interference analysis and mapping, and randomness in frequency, space and time.

+&+Rajendra+BLR+&+BCC.jpg)

+&+LRCM.jpg)